Image 1 of 10

Image 1 of 10

Image 2 of 10

Image 2 of 10

Image 3 of 10

Image 3 of 10

Image 4 of 10

Image 4 of 10

Image 5 of 10

Image 5 of 10

Image 6 of 10

Image 6 of 10

Image 7 of 10

Image 7 of 10

Image 8 of 10

Image 8 of 10

Image 9 of 10

Image 9 of 10

Image 10 of 10

Image 10 of 10

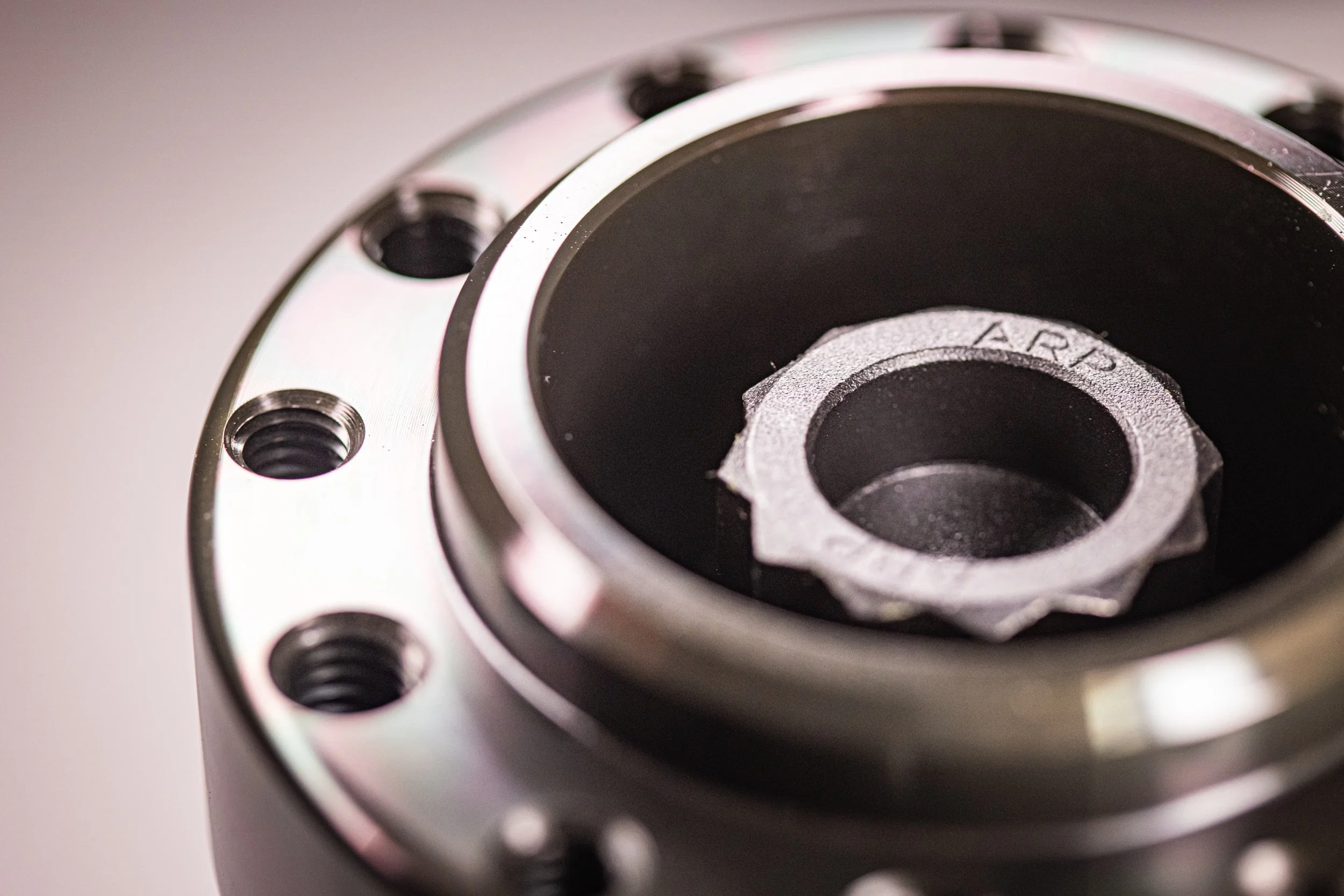

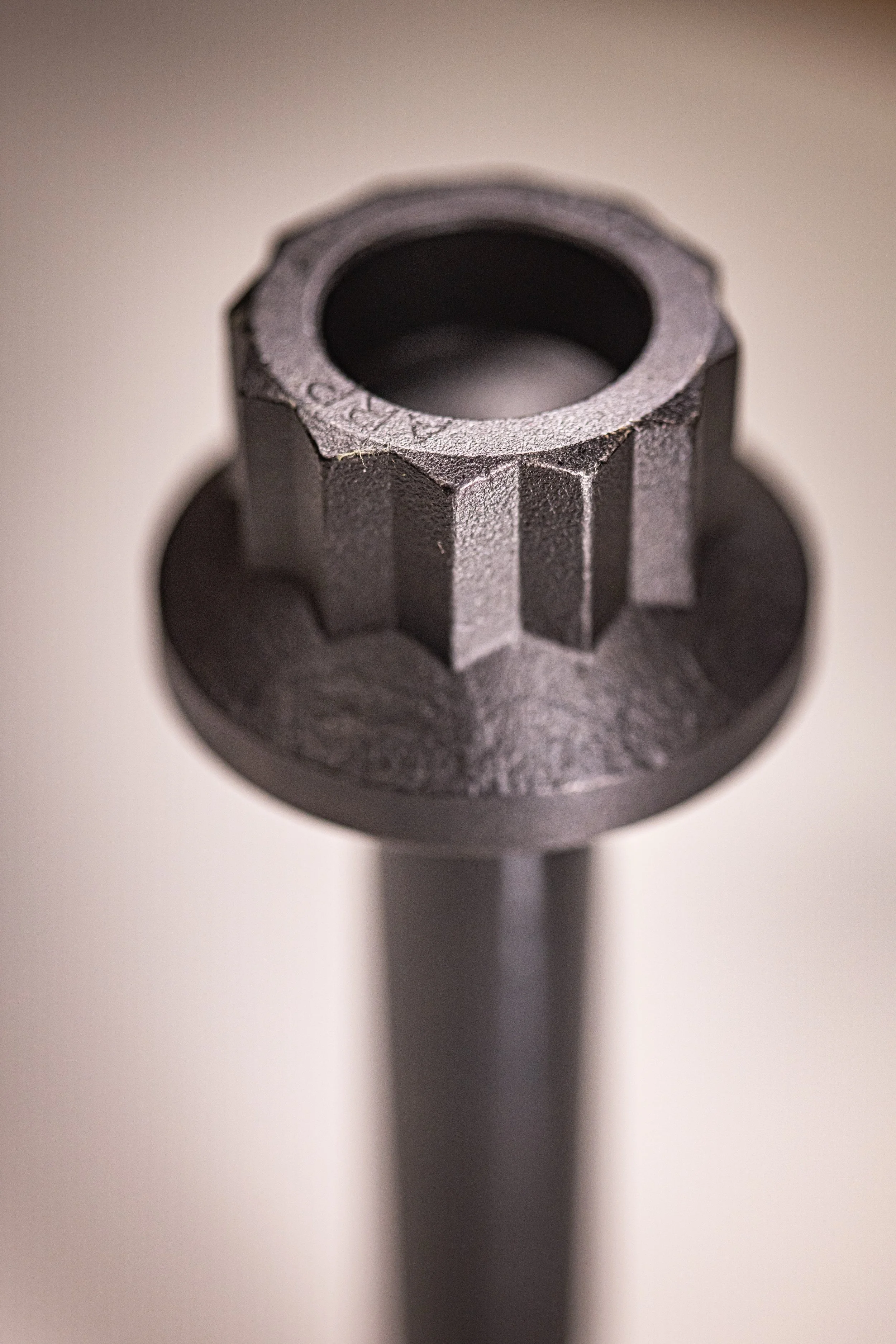

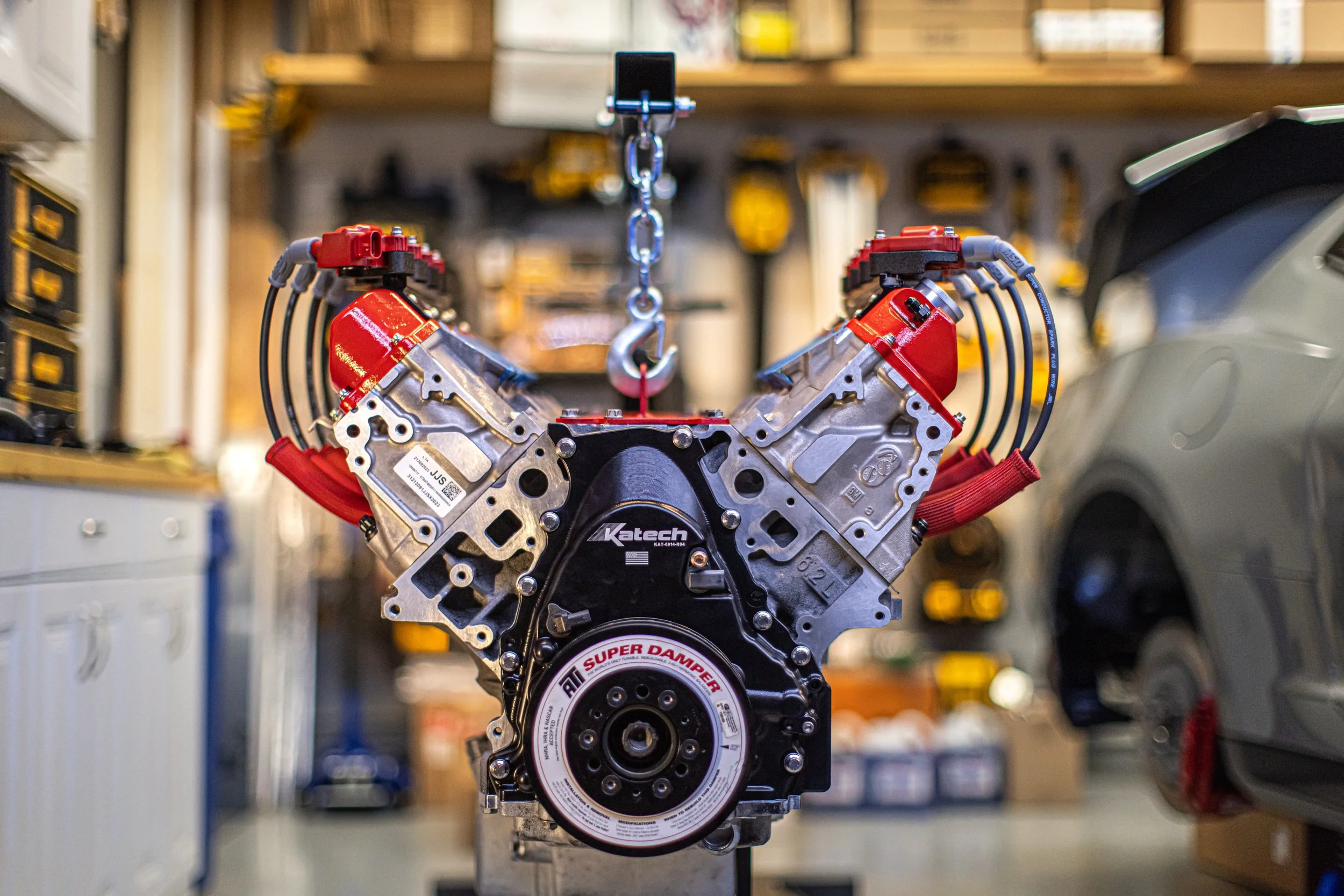

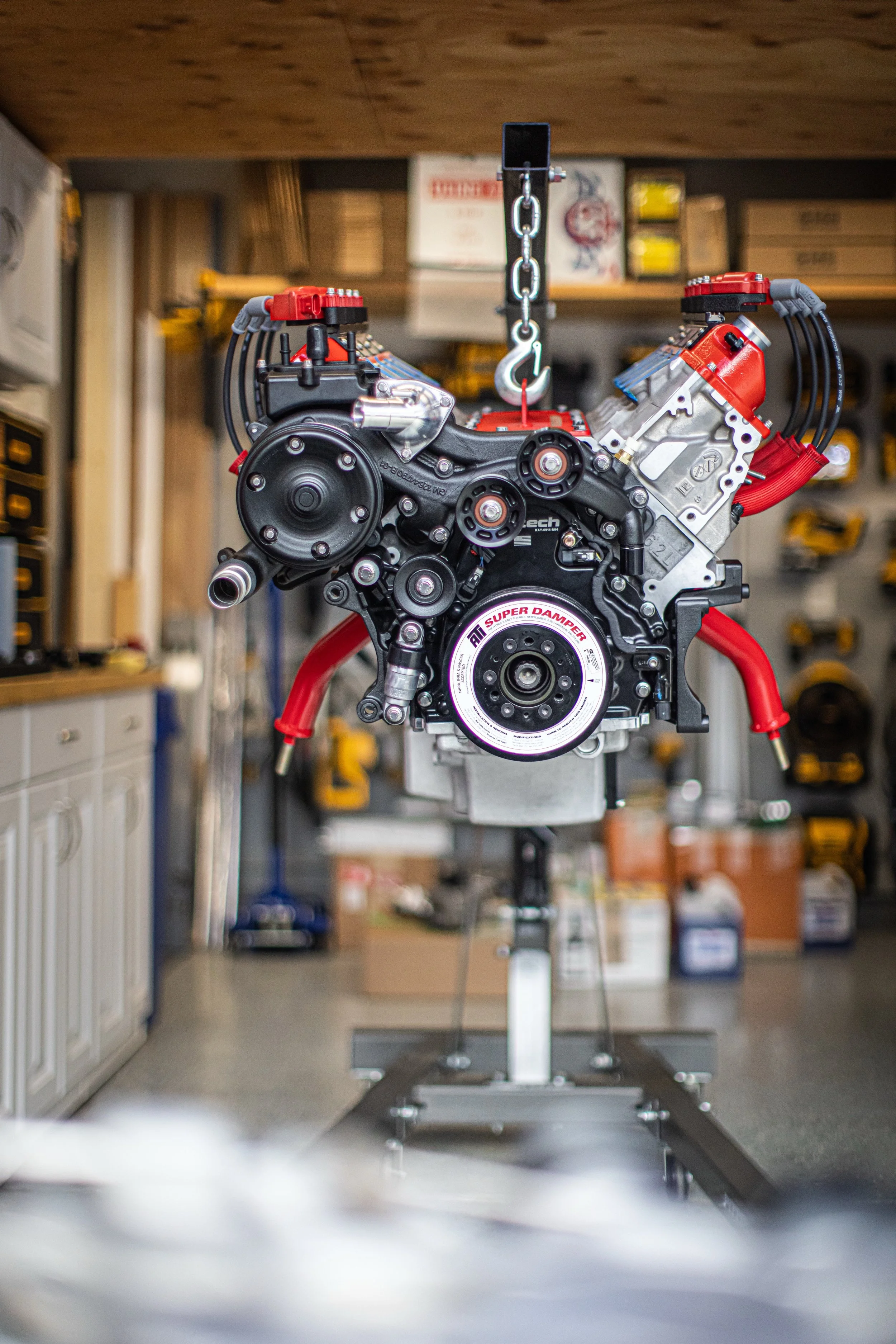

ARP Gen V LT Engine Timing Cover Bolt Set

ARP Front Timing Cover Bolt Kit – GM Gen V LT #ARP 434-1505

Perfect balance of form, and function…

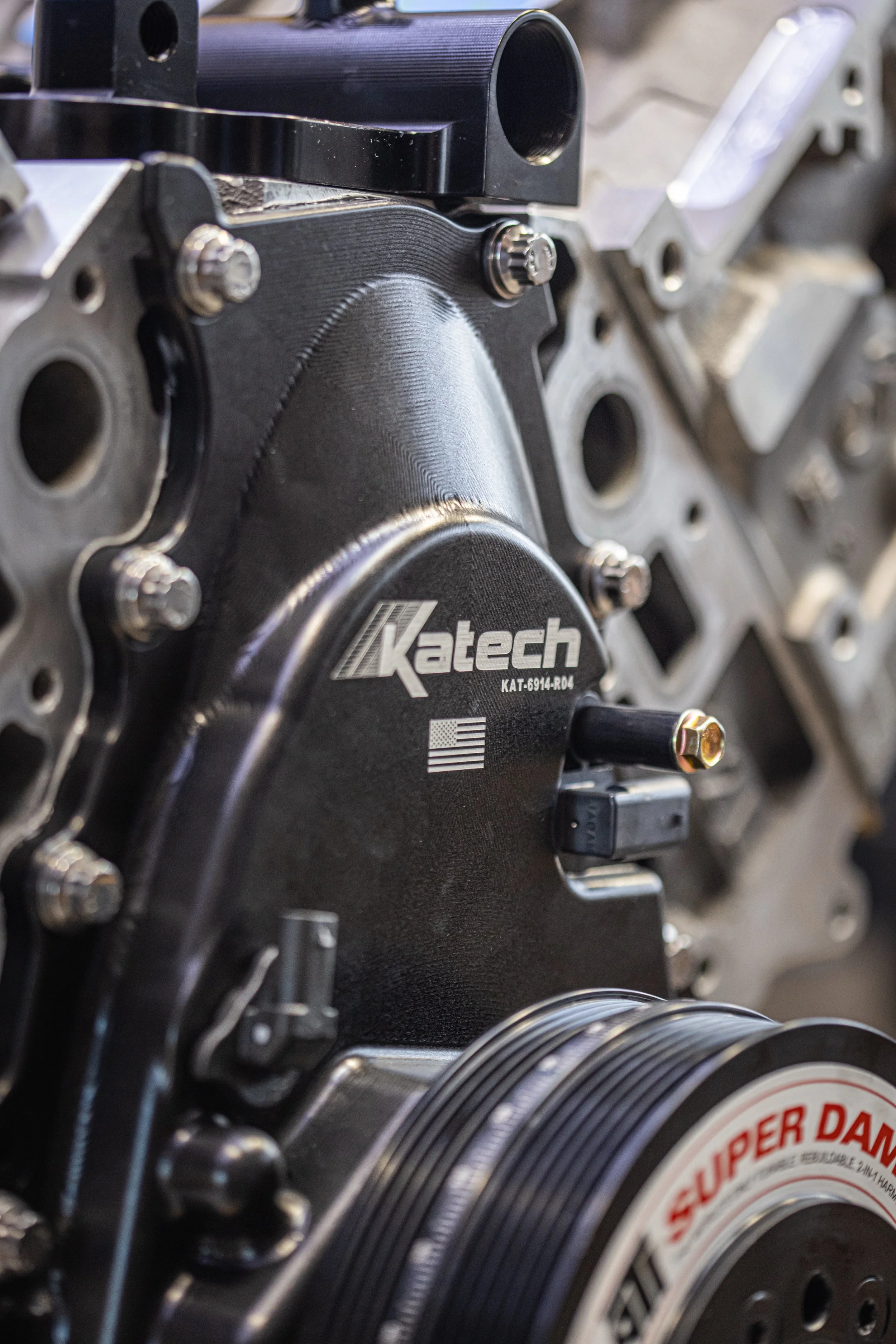

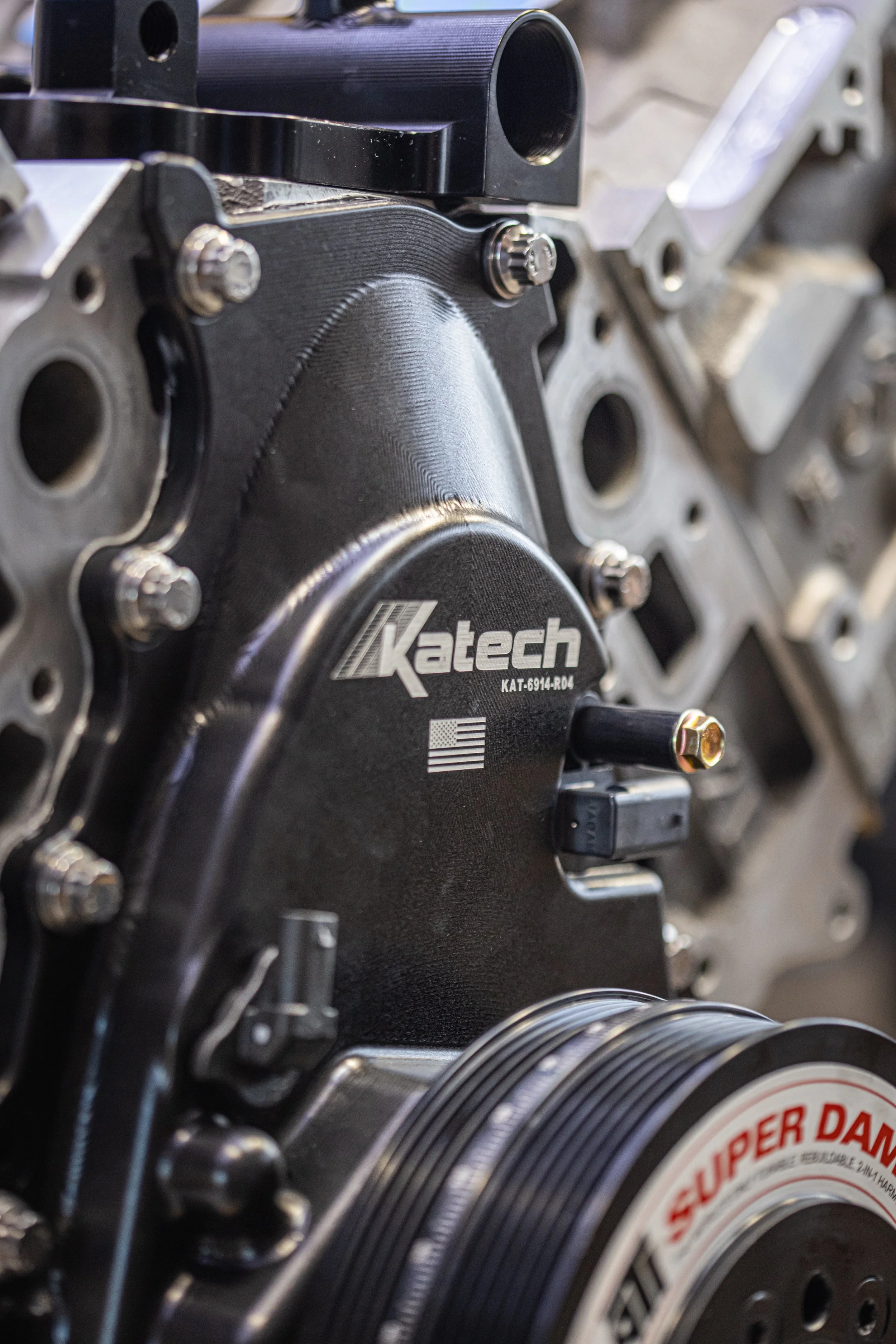

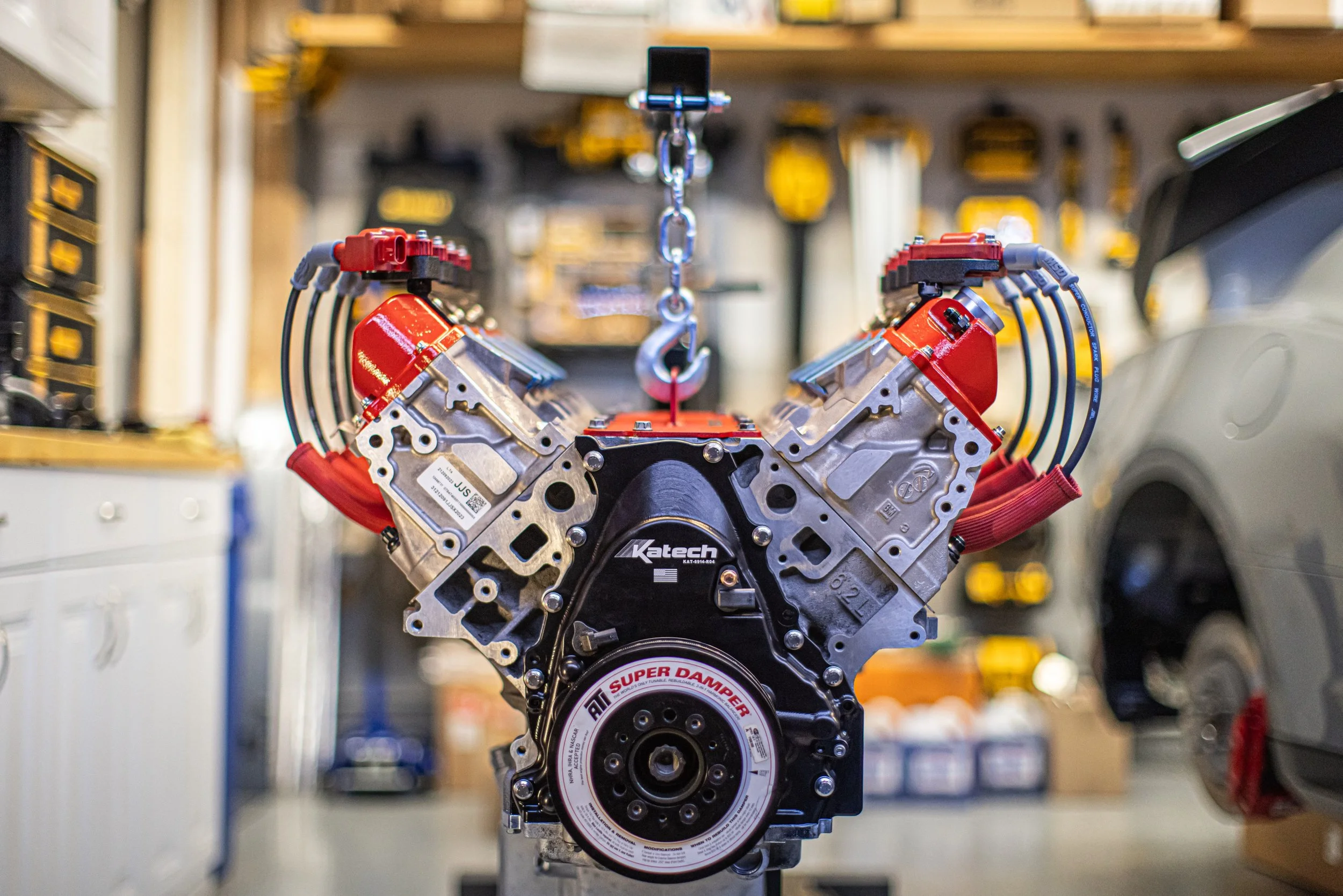

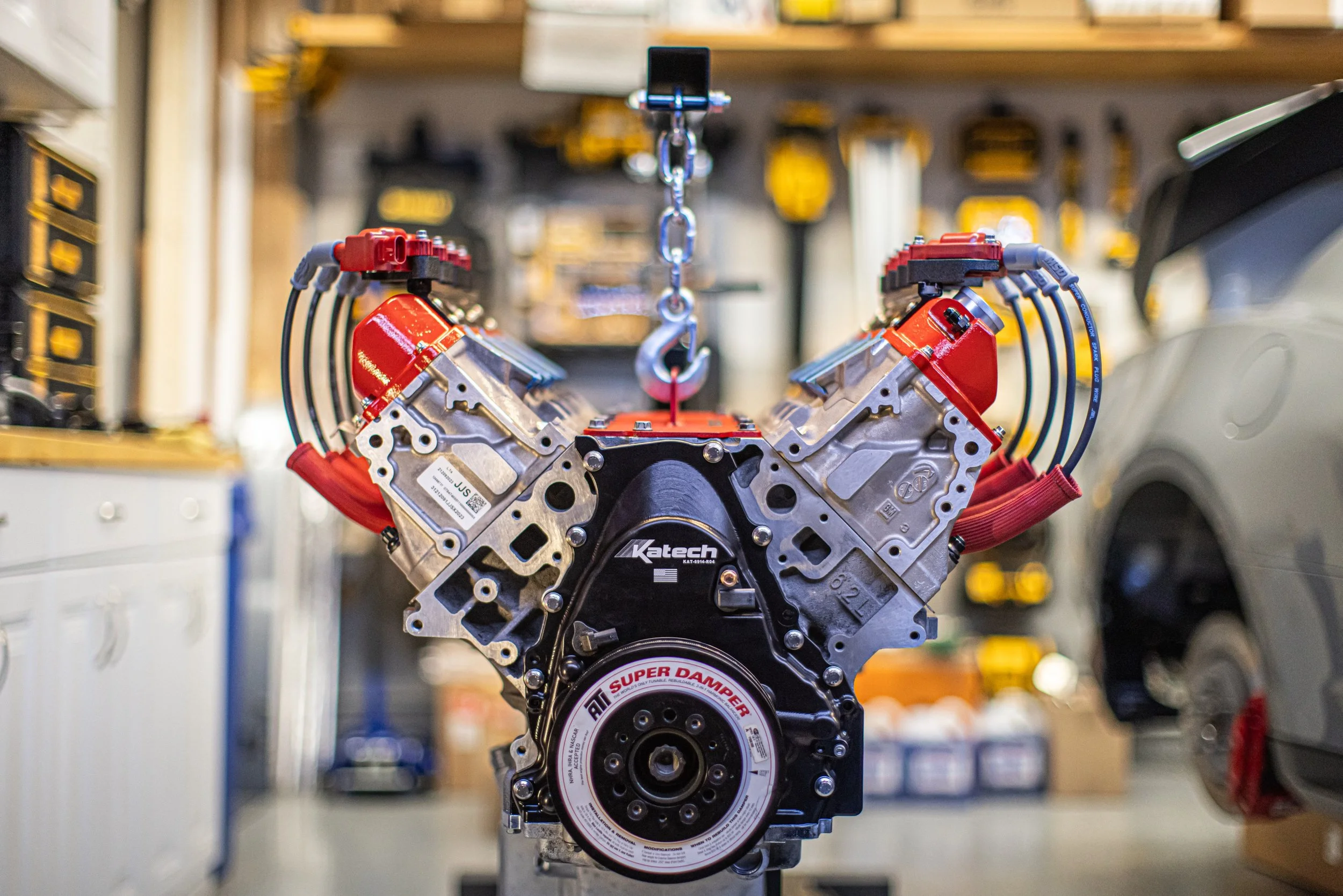

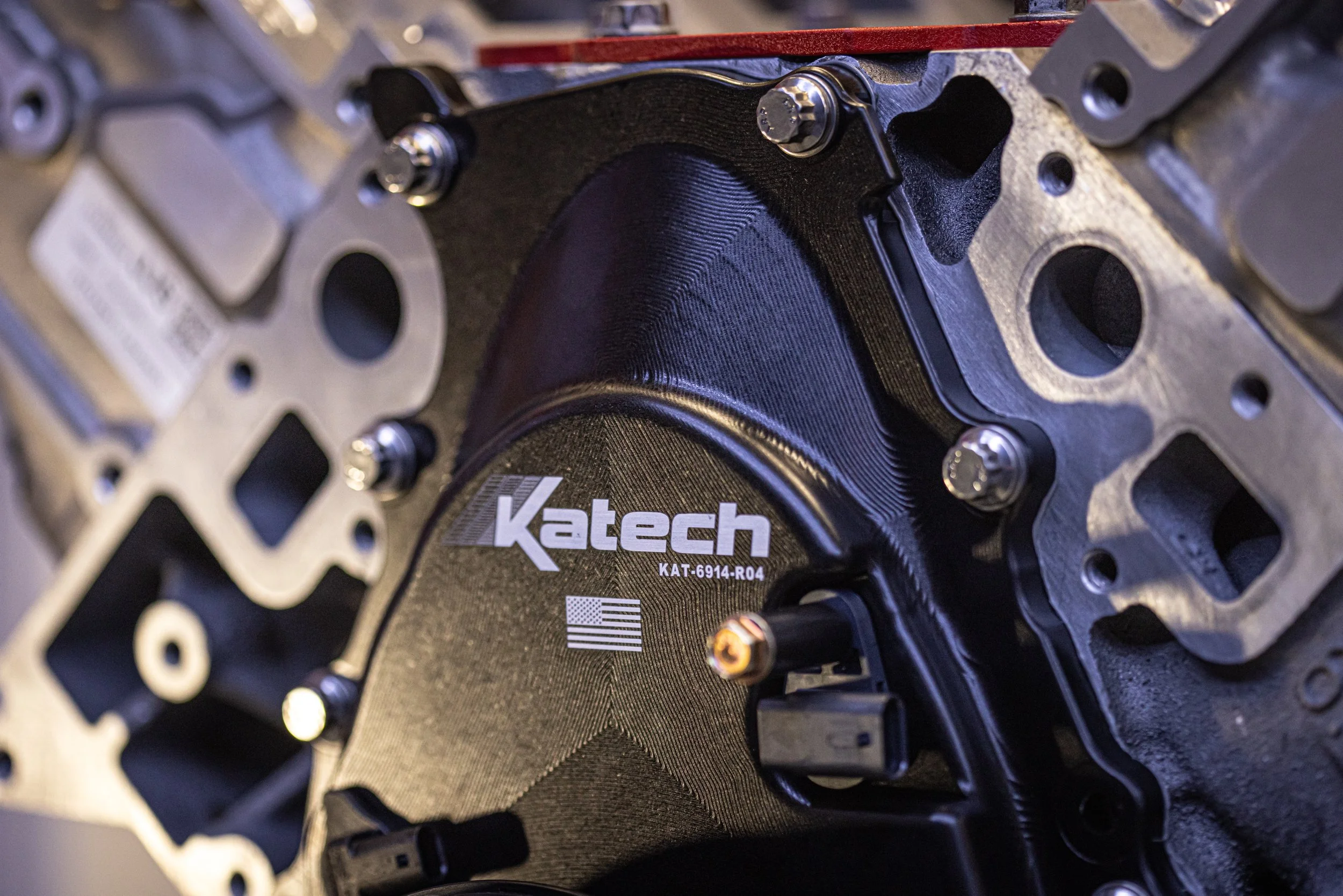

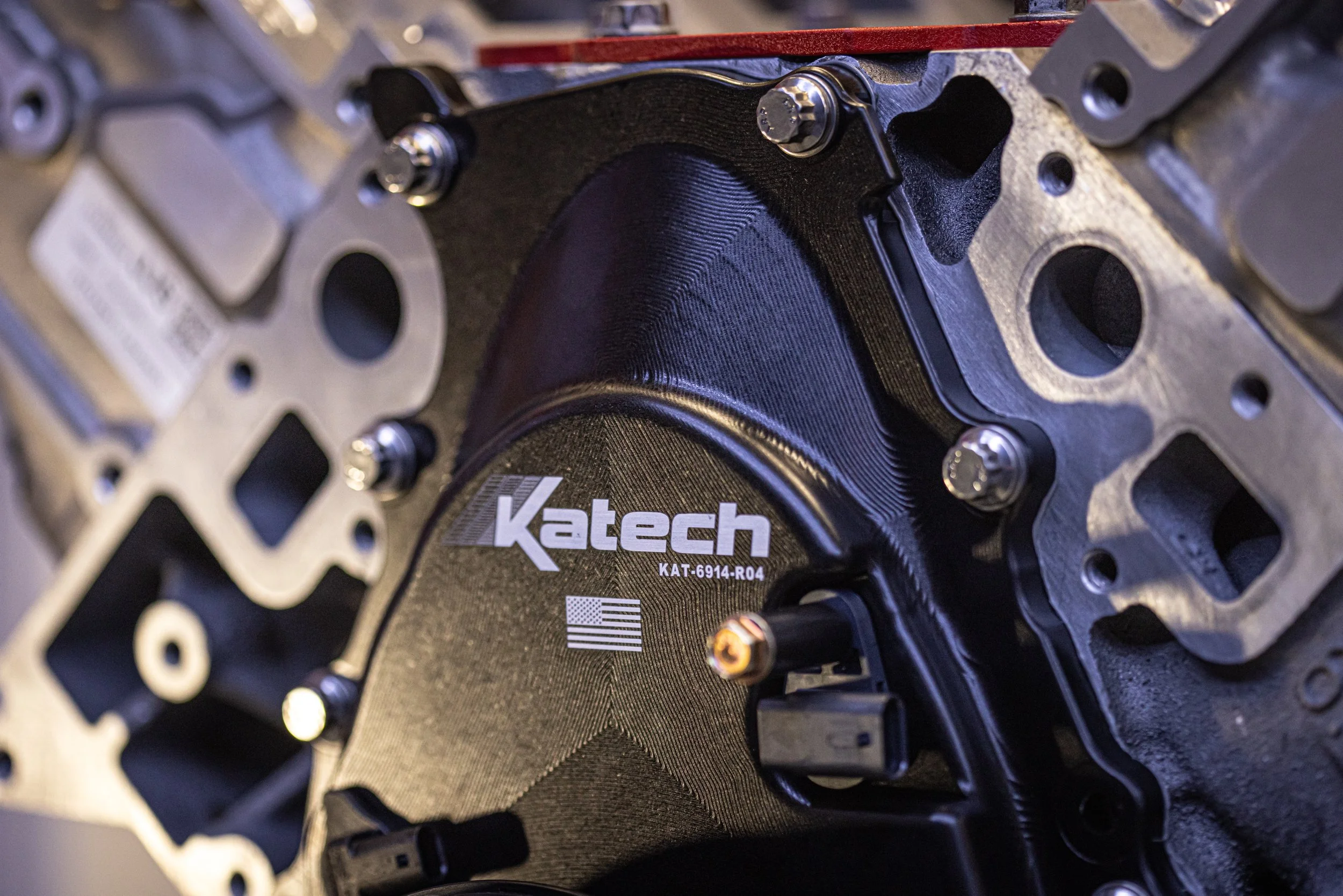

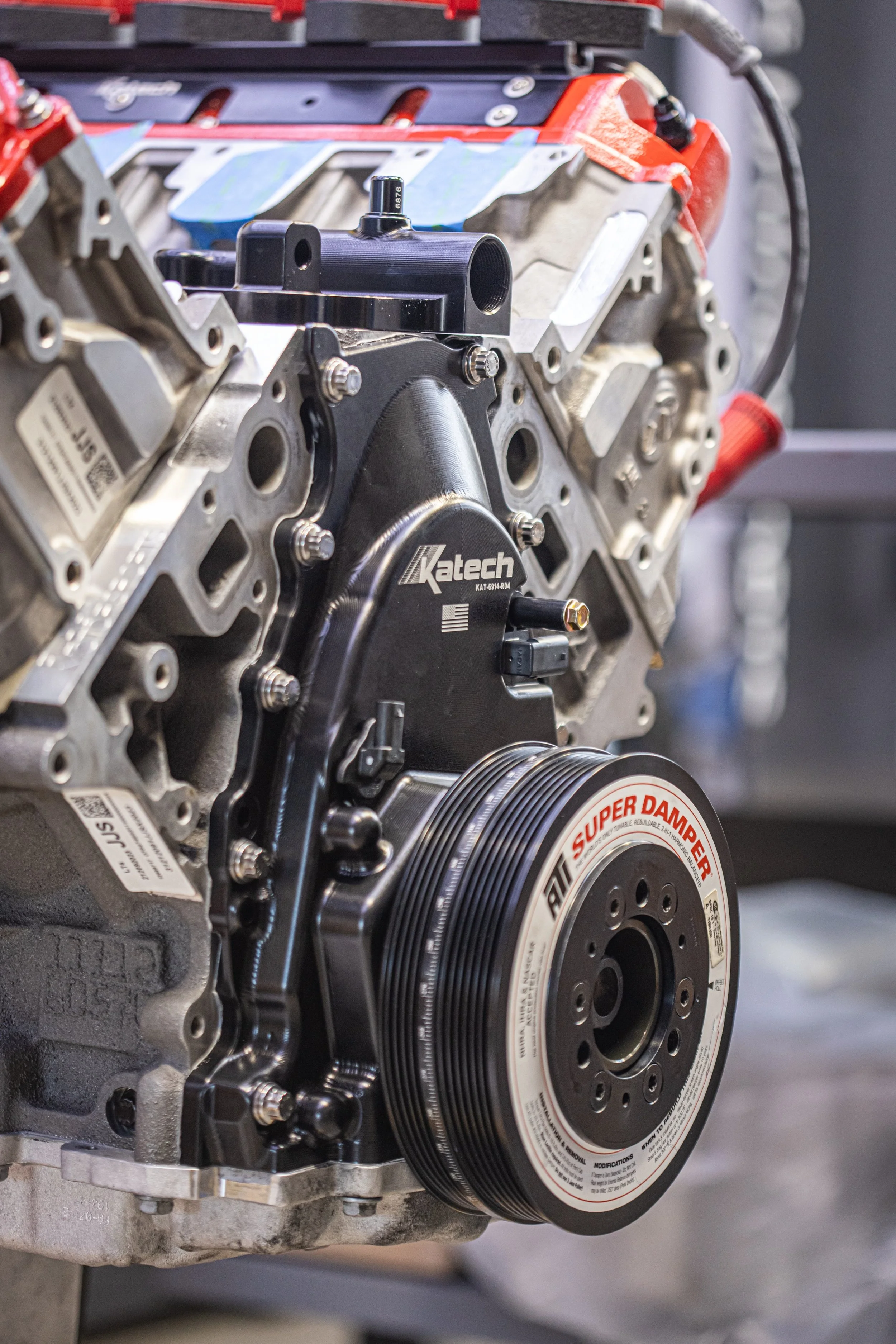

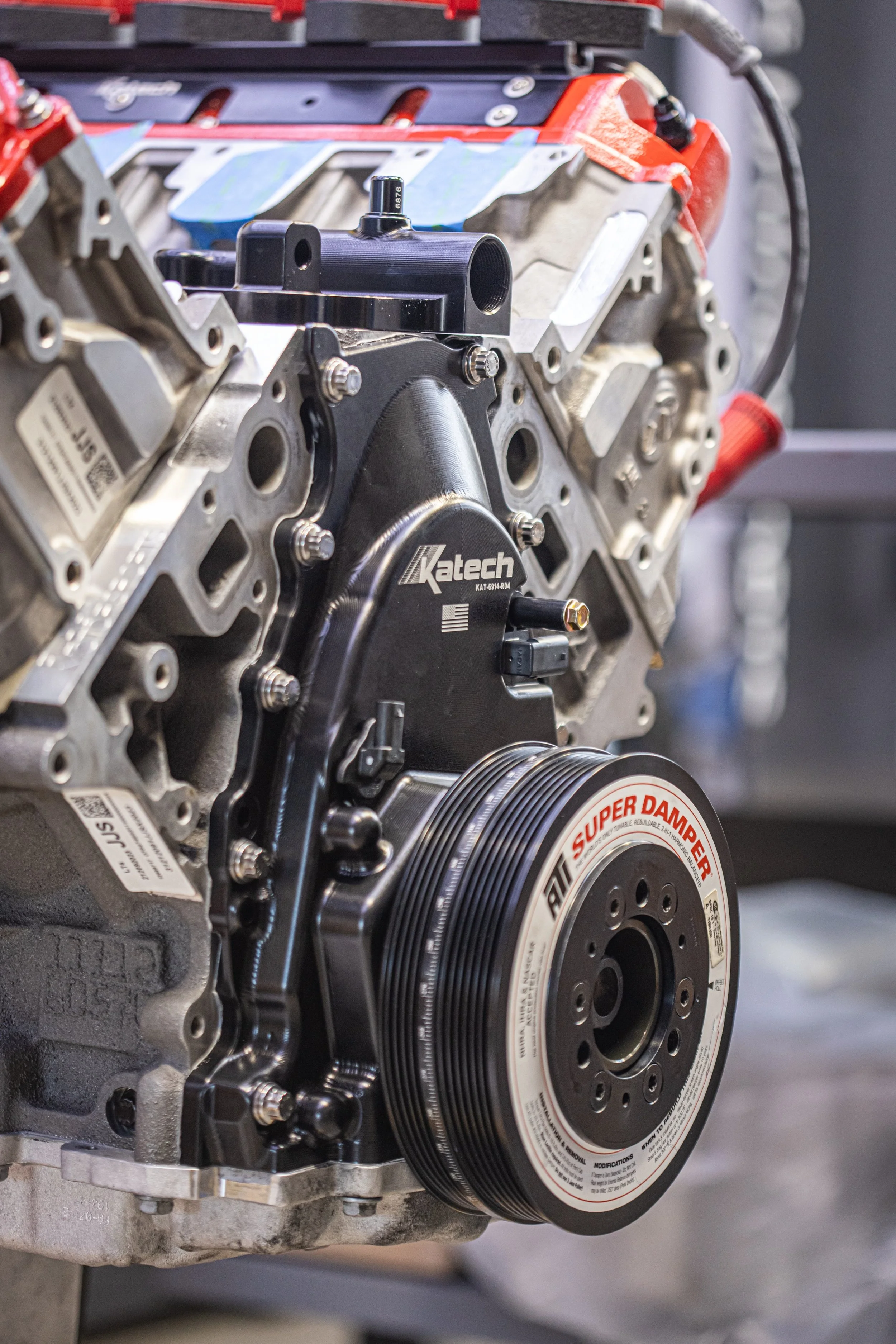

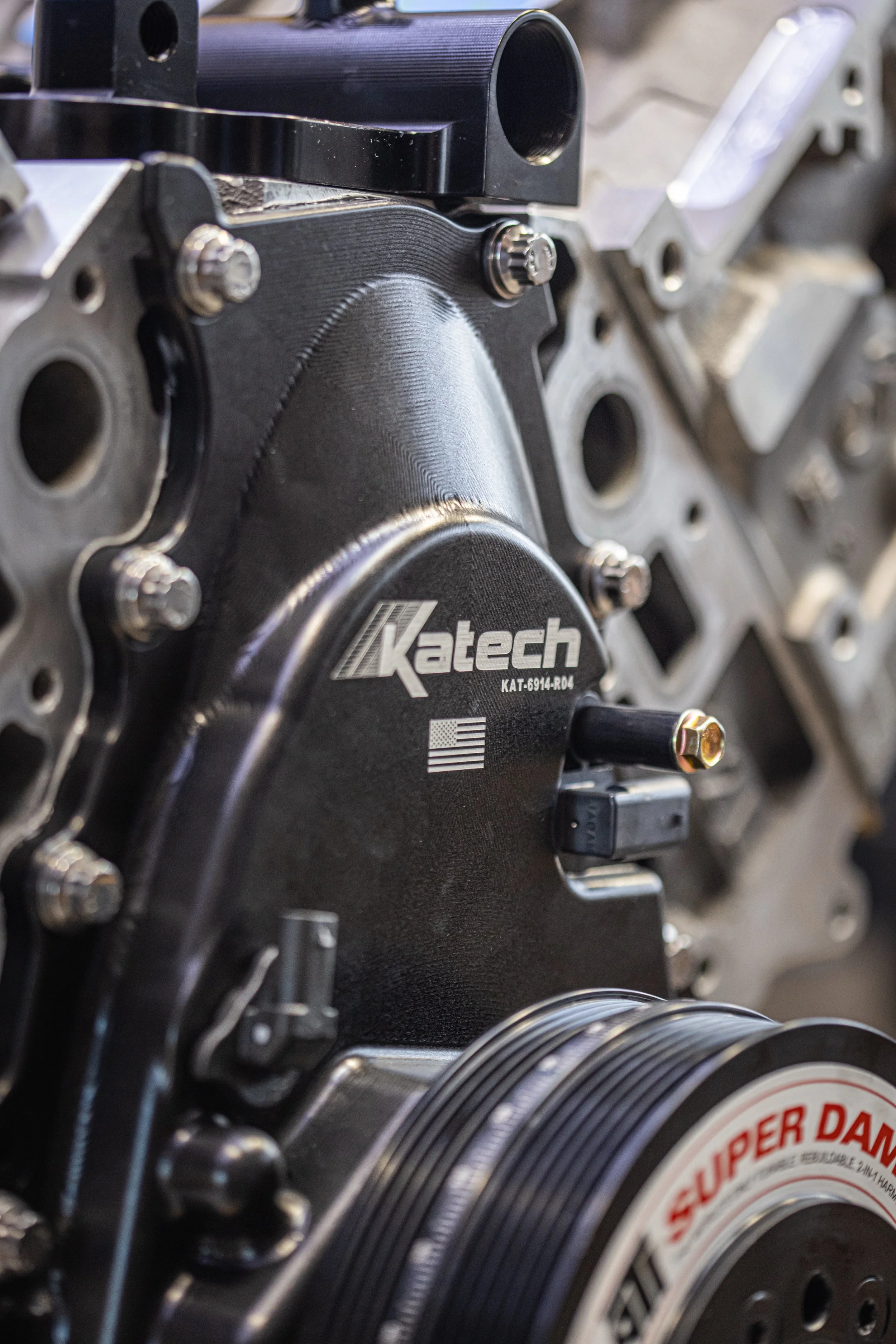

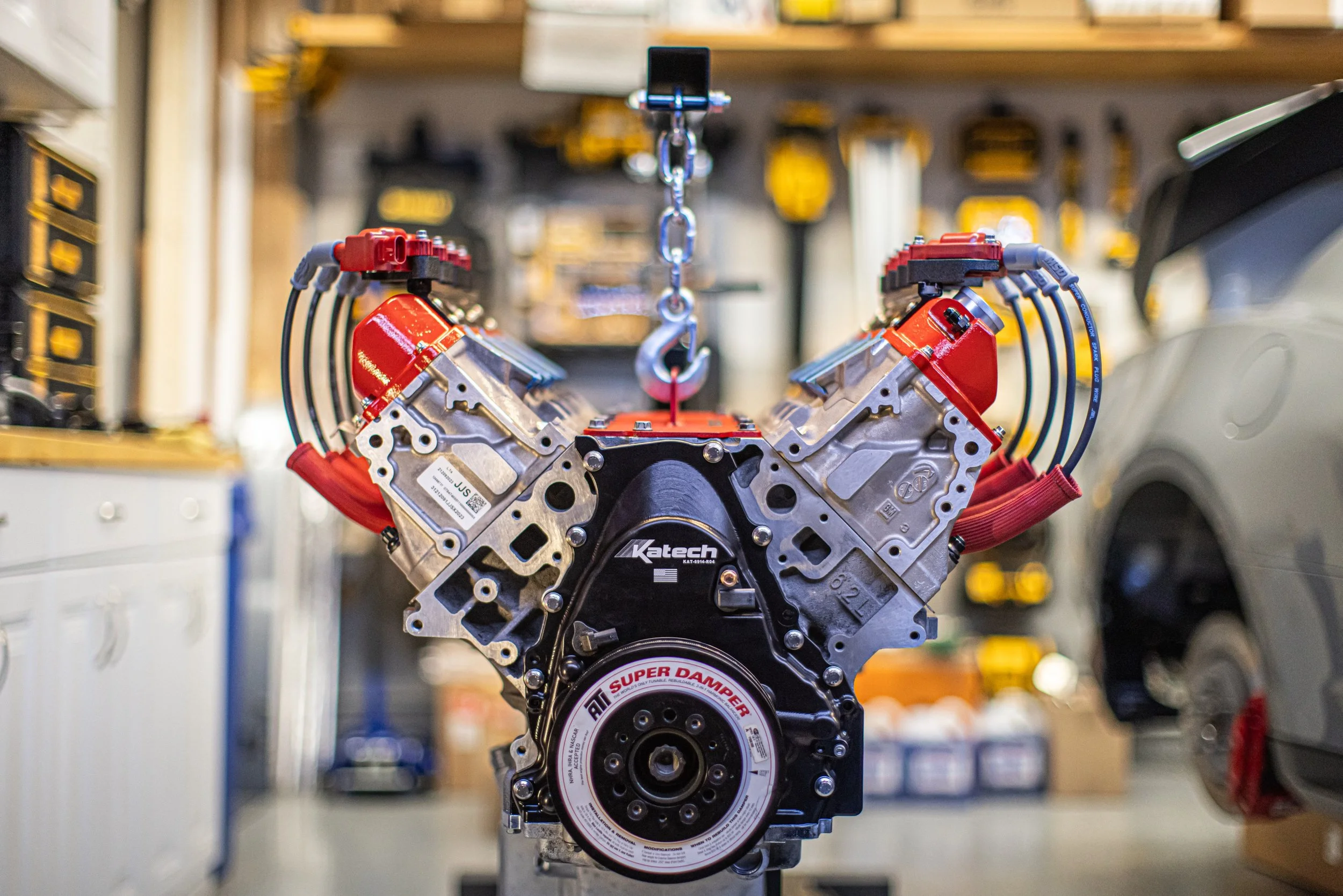

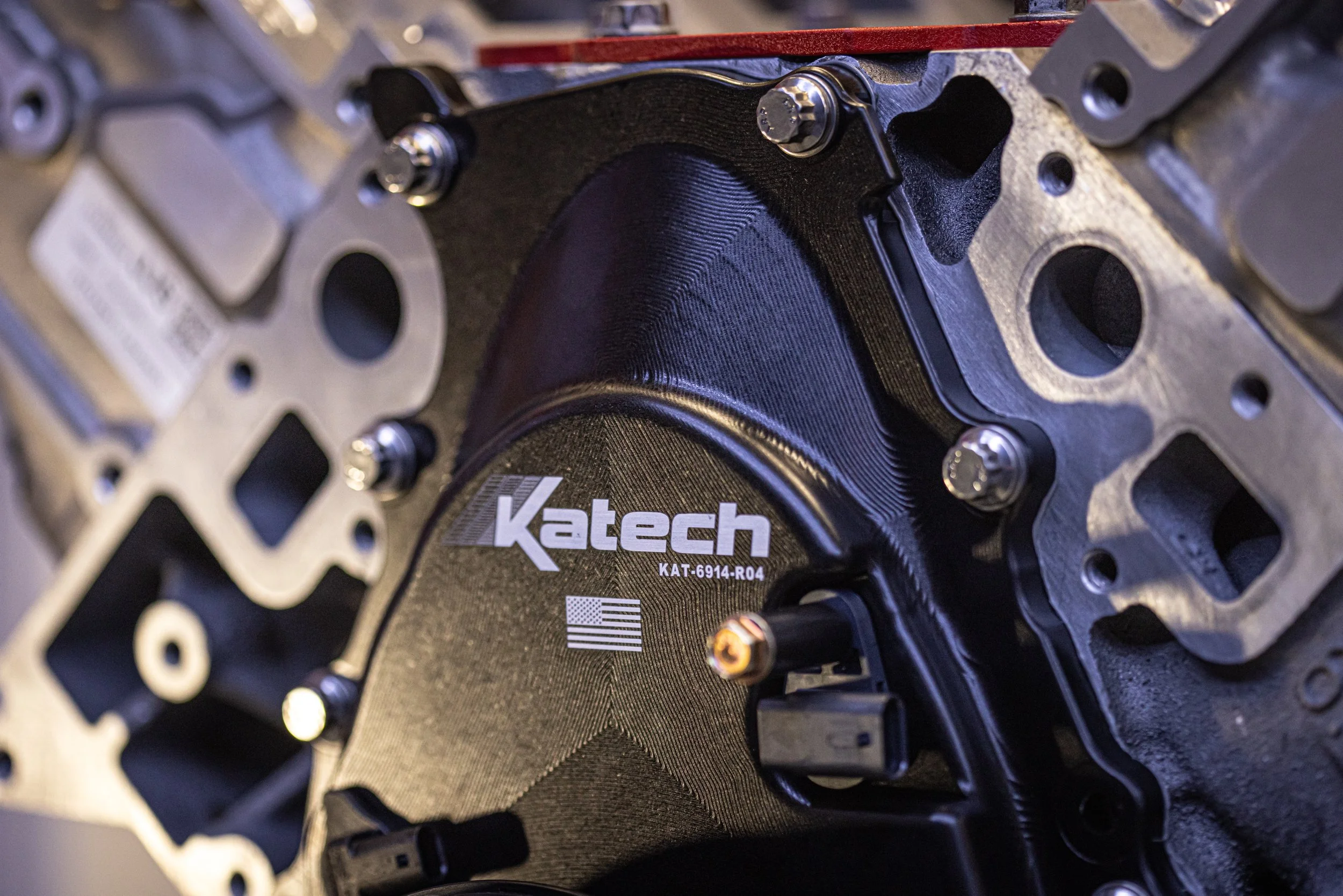

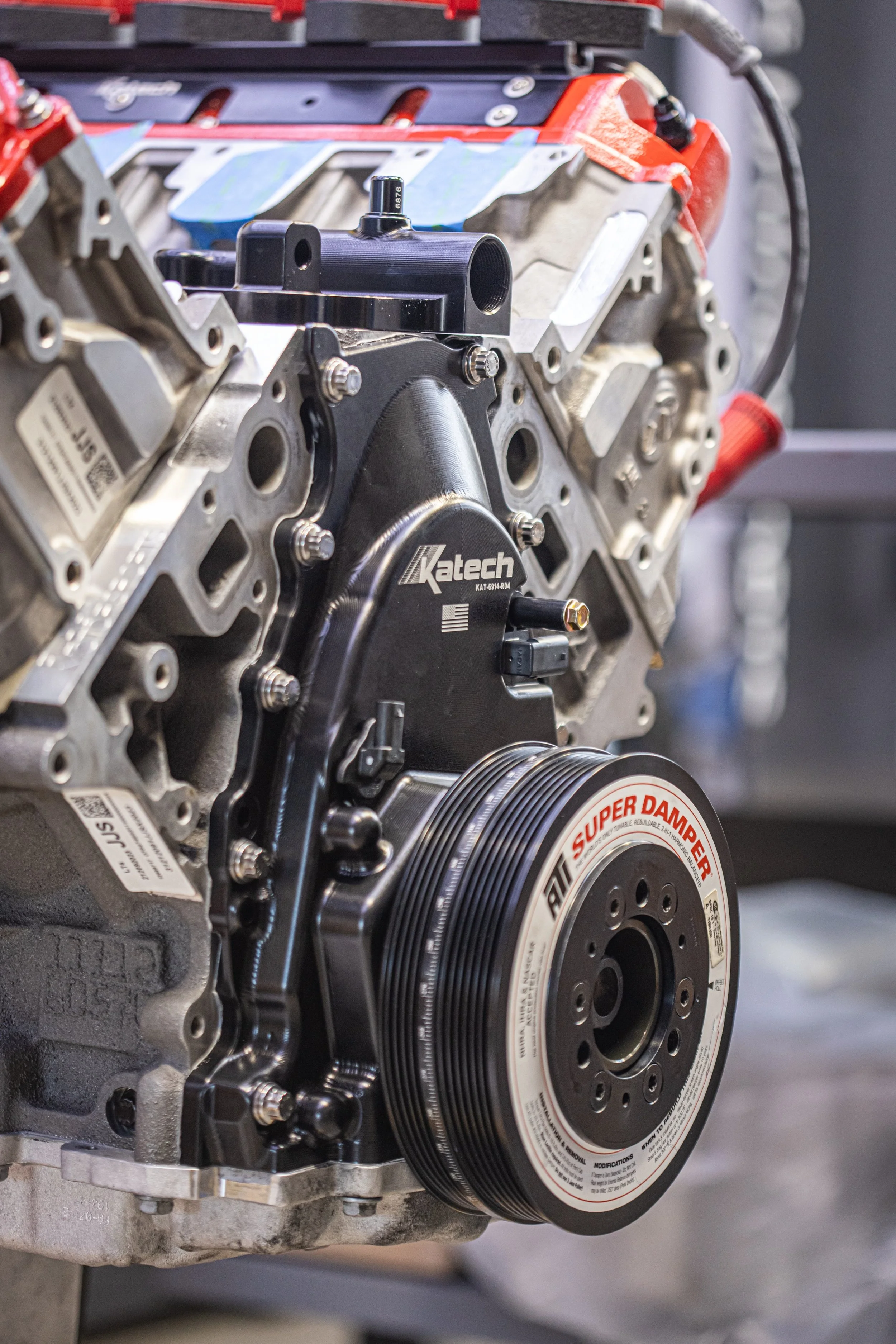

When you want your engine build to look as good as it performs, we look to our friends at Katech for there billet aluminum front and valley covers, as well as there award winning cast aluminum valve covers and coil relocation kit for most of our engine builds. When you are going to that level of attention to detail, re-installing the factory fasteners would be a crime, which is why we upgraded all of them with ARP’s premium polished stainless steel 12-point drive bolts that are specifically designed for GM’s Gen V LT engines.

These fasteners are engineered and rated over 170,000+ psi tensile strength—stronger than standard Grade 8 bolts—so you get consistent clamp load, better gasket control, and far less risk of warpage or leaks as temperatures climb.

The polished stainless finish doesn’t just look good in engine-bay photos; it resists corrosion, galling, and ugly rust bloom that can show up on factory hardware in real-world track and street environments. Add the 12-point head design and proper ARP washers, and you get repeatable torque, more uniform loading around each bolt, and easier wrench access in tight spots.

Are these bolts partially decorative? Absolutely—and that’s the point. They’re form and function. On a clean LT engine bay, the polished 12-point ARP heads instantly tell a story: this isn’t a thrown-together budget combo; someone cared enough to do the details right, and spared no expense. But behind the “show car” shine is real engineering: higher strength, better materials, and hardware built to live in the harshest conditions—boost, E, heat, and endless track days.

At Griffin Motorsports, performance and reliability will always come first—but we believe a truly great build should lookas good as it performs. Alongside pushing for faster lap times and cooler operating temps, we constantly view our products through what we call the “Cars & Coffee lens”—that moment when the hood pops and the details tell the story. Clean hardware. Purposeful engineering. A consistent, premium aesthetic. That mindset led us to upgrade our own builds to ARP stainless 12-point fasteners throughout the engine bay, and the response has been massive. After countless customers asking for a simple, turn-key way to achieve the same look and quality, we knew it was time to make it easier than ever to level up both form and function.

Key Features & Benefits

Engineered for GM Gen V LT platforms

Designed specifically for modern LT engines, not a generic universal kit. Proper lengths, thread engagement, and head style for the front timing cover on Gen V LT applications.

High-strength ARP300 stainless construction

ARP’s proprietary stainless is rated around 170,000+ psi tensile strength—stronger than Grade 8—providing superior clamping force and long-term reliability under boost, heat, and high RPM.

12-point polished heads – function with a flex

12-point head design offers better tool engagement and access in tight spaces, while the polished finish gives your timing cover area a clean, high-end look that stands out in engine-bay photos.

Corrosion and galling resistance

Unlike standard steel bolts that corrode and stain, ARP300 stainless holds its finish, even in humid or coastal environments, making it ideal for street cars, track cars, and long-term builds.

Improved sealing and gasket control

Consistent clamp load helps keep the timing cover flat and the gasket properly compressed, reducing the risk of front cover oil seepage and long-term leaks as the engine sees thermal cycling and vibration.

Show-car detail, race-car mindset

Yes, they’re decorative—because the details matter. But every “pretty” choice here is backed by mechanical advantage: better material, better head design, better sealing.

Bundle and save with our ARP bundle packages

Combine these with several other solutions in order to make your build look as good as it runs… for less.

Fitment Guide

Engine Platform:

* GM Gen V LT-based engines (2014+)

Confirmed Engine Applications:

* 5.3L: L82, L83, L84

* 6.2L: LT1, LT2, LT4, L86, L87, L8T

Typical Vehicle Applications (2014+ depending on engine configuration):

*Chevrolet Camaro – LT1 / SS / ZL1 with LT-series engines

*Chevrolet Corvette – C7 Stingray, Grand Sport, Z06 (LT1 / LT4)

*Chevrolet Silverado / GMC Sierra – 1500 & HD models equipped with Gen V 5.3L/6.2L LT truck engines

*Chevrolet Tahoe / Suburban / GMC Yukon / Cadillac Escalade – with Gen V LT-based 5.3L/6.2L engines

Installation Notes

Always clean bolt holes and threads before installation (chasing with a tap is recommended on high-mileage or previously corroded blocks).

Use ARP’s recommended lubricant and torque specs for the most accurate clamp load.

Torque in a cross-pattern to help keep the timing cover flat and the gasket evenly compressed.

ARP Front Timing Cover Bolt Kit – GM Gen V LT #ARP 434-1505

Perfect balance of form, and function…

When you want your engine build to look as good as it performs, we look to our friends at Katech for there billet aluminum front and valley covers, as well as there award winning cast aluminum valve covers and coil relocation kit for most of our engine builds. When you are going to that level of attention to detail, re-installing the factory fasteners would be a crime, which is why we upgraded all of them with ARP’s premium polished stainless steel 12-point drive bolts that are specifically designed for GM’s Gen V LT engines.

These fasteners are engineered and rated over 170,000+ psi tensile strength—stronger than standard Grade 8 bolts—so you get consistent clamp load, better gasket control, and far less risk of warpage or leaks as temperatures climb.

The polished stainless finish doesn’t just look good in engine-bay photos; it resists corrosion, galling, and ugly rust bloom that can show up on factory hardware in real-world track and street environments. Add the 12-point head design and proper ARP washers, and you get repeatable torque, more uniform loading around each bolt, and easier wrench access in tight spots.

Are these bolts partially decorative? Absolutely—and that’s the point. They’re form and function. On a clean LT engine bay, the polished 12-point ARP heads instantly tell a story: this isn’t a thrown-together budget combo; someone cared enough to do the details right, and spared no expense. But behind the “show car” shine is real engineering: higher strength, better materials, and hardware built to live in the harshest conditions—boost, E, heat, and endless track days.

At Griffin Motorsports, performance and reliability will always come first—but we believe a truly great build should lookas good as it performs. Alongside pushing for faster lap times and cooler operating temps, we constantly view our products through what we call the “Cars & Coffee lens”—that moment when the hood pops and the details tell the story. Clean hardware. Purposeful engineering. A consistent, premium aesthetic. That mindset led us to upgrade our own builds to ARP stainless 12-point fasteners throughout the engine bay, and the response has been massive. After countless customers asking for a simple, turn-key way to achieve the same look and quality, we knew it was time to make it easier than ever to level up both form and function.

Key Features & Benefits

Engineered for GM Gen V LT platforms

Designed specifically for modern LT engines, not a generic universal kit. Proper lengths, thread engagement, and head style for the front timing cover on Gen V LT applications.

High-strength ARP300 stainless construction

ARP’s proprietary stainless is rated around 170,000+ psi tensile strength—stronger than Grade 8—providing superior clamping force and long-term reliability under boost, heat, and high RPM.

12-point polished heads – function with a flex

12-point head design offers better tool engagement and access in tight spaces, while the polished finish gives your timing cover area a clean, high-end look that stands out in engine-bay photos.

Corrosion and galling resistance

Unlike standard steel bolts that corrode and stain, ARP300 stainless holds its finish, even in humid or coastal environments, making it ideal for street cars, track cars, and long-term builds.

Improved sealing and gasket control

Consistent clamp load helps keep the timing cover flat and the gasket properly compressed, reducing the risk of front cover oil seepage and long-term leaks as the engine sees thermal cycling and vibration.

Show-car detail, race-car mindset

Yes, they’re decorative—because the details matter. But every “pretty” choice here is backed by mechanical advantage: better material, better head design, better sealing.

Bundle and save with our ARP bundle packages

Combine these with several other solutions in order to make your build look as good as it runs… for less.

Fitment Guide

Engine Platform:

* GM Gen V LT-based engines (2014+)

Confirmed Engine Applications:

* 5.3L: L82, L83, L84

* 6.2L: LT1, LT2, LT4, L86, L87, L8T

Typical Vehicle Applications (2014+ depending on engine configuration):

*Chevrolet Camaro – LT1 / SS / ZL1 with LT-series engines

*Chevrolet Corvette – C7 Stingray, Grand Sport, Z06 (LT1 / LT4)

*Chevrolet Silverado / GMC Sierra – 1500 & HD models equipped with Gen V 5.3L/6.2L LT truck engines

*Chevrolet Tahoe / Suburban / GMC Yukon / Cadillac Escalade – with Gen V LT-based 5.3L/6.2L engines

Installation Notes

Always clean bolt holes and threads before installation (chasing with a tap is recommended on high-mileage or previously corroded blocks).

Use ARP’s recommended lubricant and torque specs for the most accurate clamp load.

Torque in a cross-pattern to help keep the timing cover flat and the gasket evenly compressed.