Image 1 of 9

Image 1 of 9

Image 2 of 9

Image 2 of 9

Image 3 of 9

Image 3 of 9

Image 4 of 9

Image 4 of 9

Image 5 of 9

Image 5 of 9

Image 6 of 9

Image 6 of 9

Image 7 of 9

Image 7 of 9

Image 8 of 9

Image 8 of 9

Image 9 of 9

Image 9 of 9

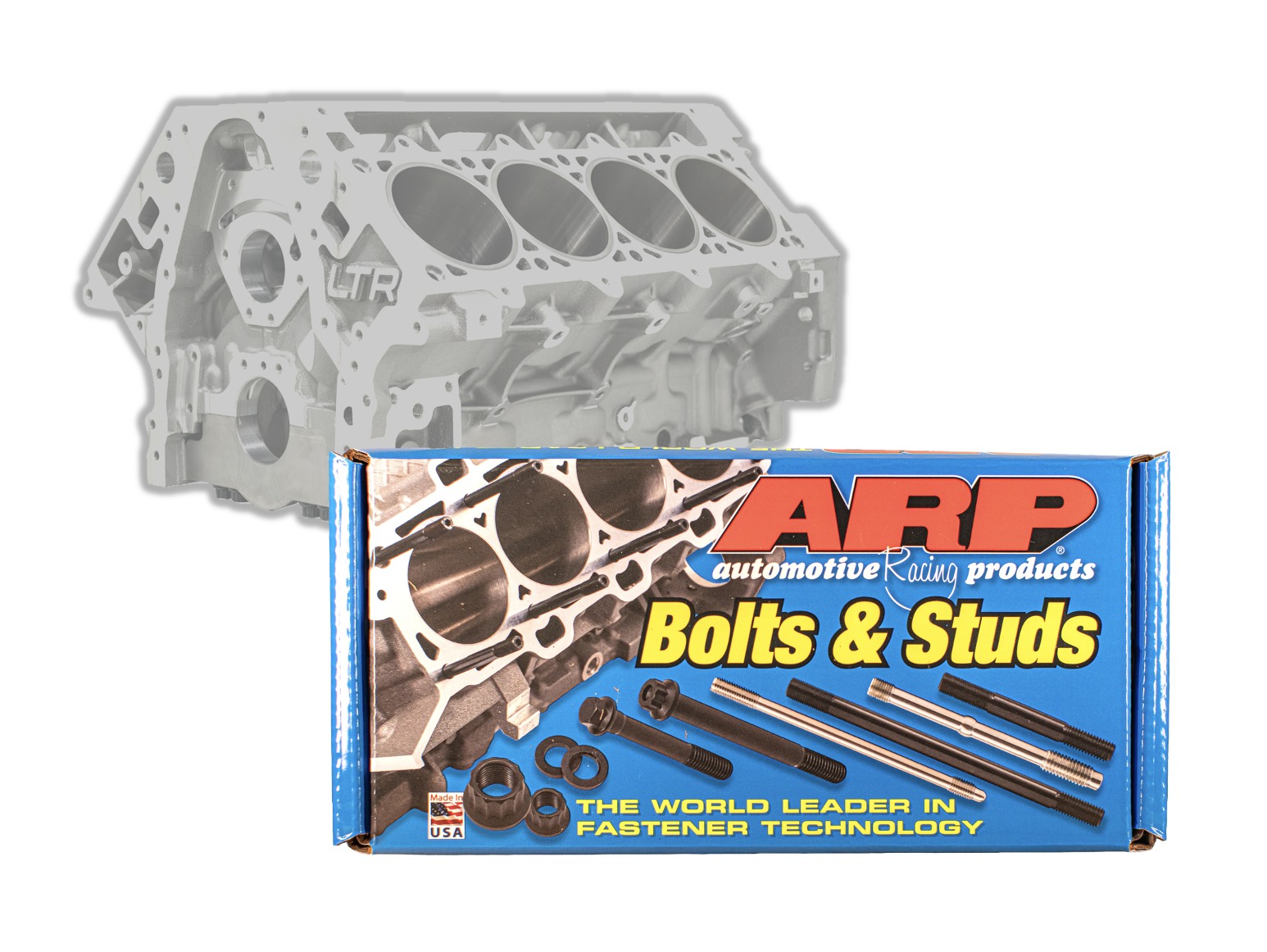

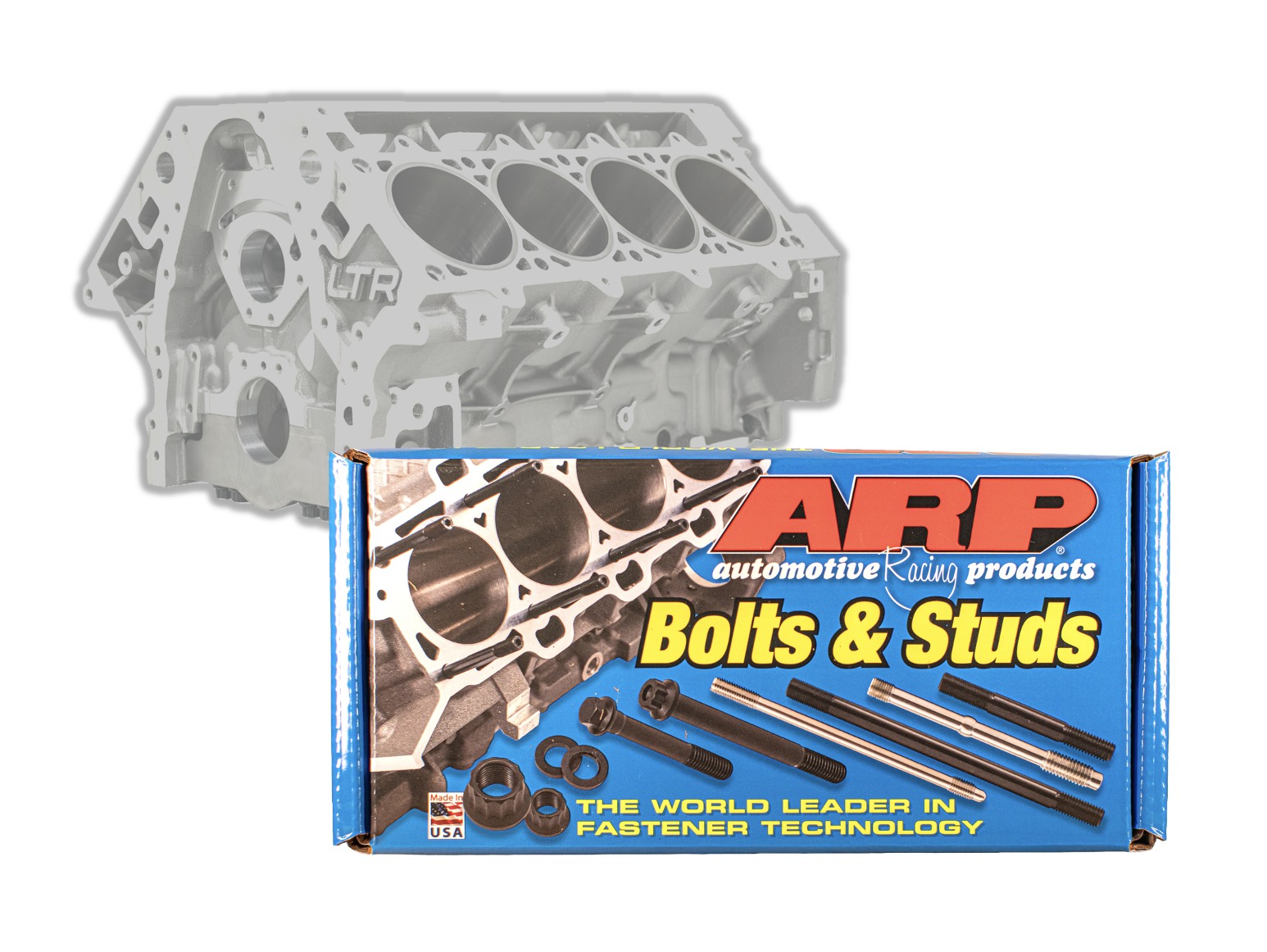

ARP Gen V LT Engine Main Stud Kit

ARP Pro Series Main Stud Kit – Gen V LT #234-5802

When you start leaning on a Gen V LT with more boost, more RPM, more timing, and a stickier tire, the bottom end becomes the foundation that either holds it all together… or quietly ruins your season.

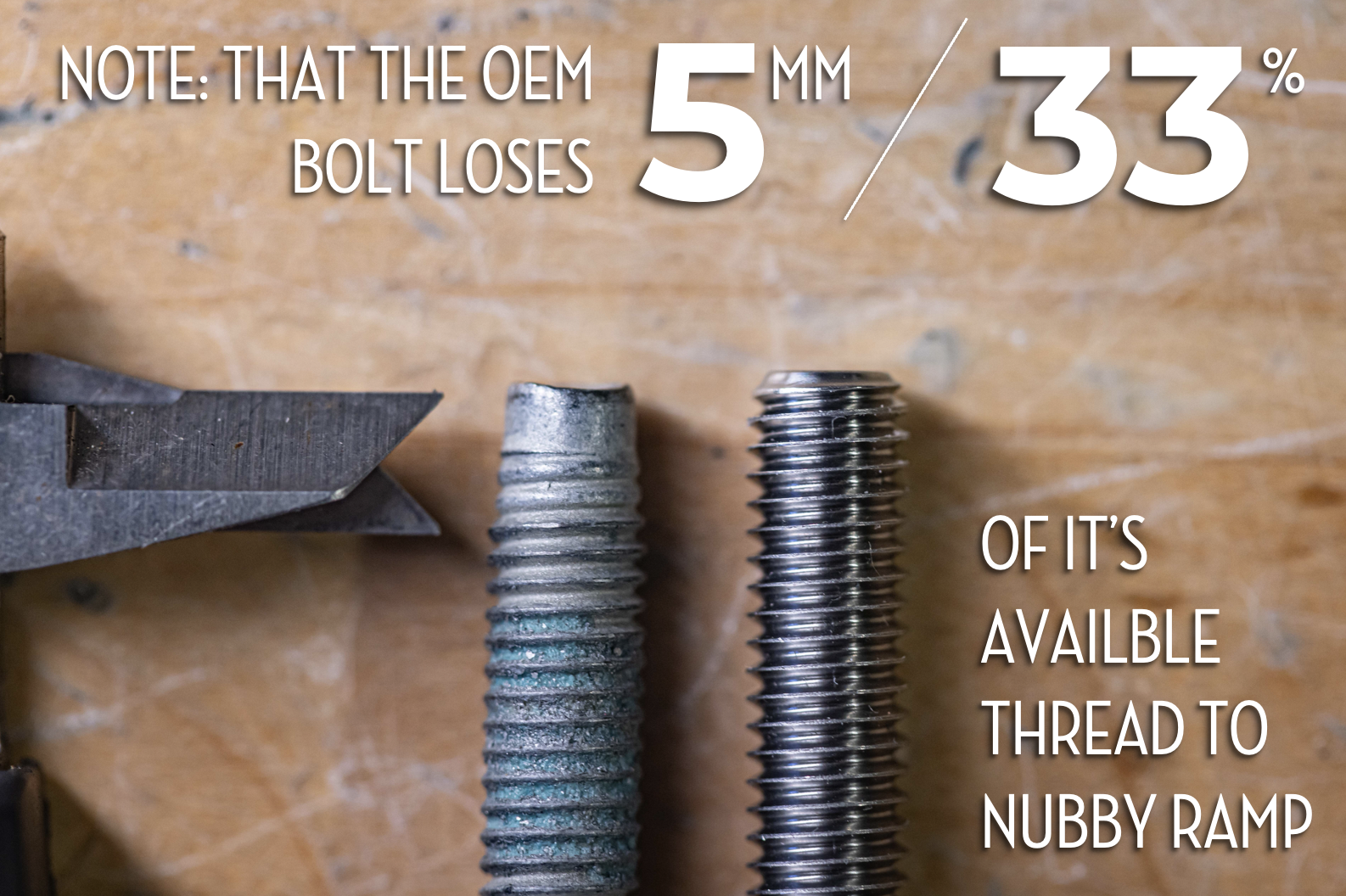

From the factory, Gen V LT engines use torque-to-yield main bolts that were never designed for the “all to common” 800-1,000 rwhp. The frustrating reality is that most “head and cam packages” seem to be 20k mile packages due to the lack of attention given to the factory shortblock and fasteners. As you increase cylinder pressure and load through simple “bolt ons”, those bolts can quickly reach their limit, allowing main cap “walk,” fretting of the registers, and crankshaft flex that hurts bearing life, ring seal, and oil control. Don’t believe me? I can send you photos from my 8,000 motor that already showed all of those signs making only 800rwhp (before we added more power).

The ARP 234-5802 Pro Series Main Stud Kit replaces those stressed OE fasteners with 8740 chromoly steel studs engineered for serious clamp load and long-term stability on all 2014+ Gen V LT-based 5.3L and 6.2L engines—LT1, LT4, LT2, truck L83/L86/L87 and more.

This is the main fastener kit we recommend any time an LT short block is apart for rods/pistons, stroker builds, power-adder combos, or sustained high-RPM use.

What Makes ARP 234-5802 Different?

1. Real Material Science – 8740 Chromoly, Heat Treated Hard

These studs are manufactured from 8740 chromoly steel, then heat treated to a nominal tensile strength around 190,000–200,000 psi—far beyond typical OEM main bolts and generic hardware.

8740 chromoly offers excellent fatigue resistance and high-cycle durability, crucial for a crank that’s constantly being hammered by boost and low RPM torque.

The high tensile rating allows more consistent and higher clamp load without permanent stretch, which is what keeps the caps locked to the registers instead of walking around under load.

2. Thread-Rolled After Heat Treat = Stronger Threads

ARP rolls the threads after heat treat and to Mil-S-8879-type specifications (J-form style), which dramatically increases thread fatigue strength compared to cut threads or rolled-before-heat-treat designs.

That matters because:

Threads become the first stress concentration when things get ugly.

Stronger threads mean the fastener is far less likely to fail at the root, even with repeated teardowns and retorques.

Along with precision centerless grinding, this gives you a stud that provides highly repeatable clamping force from one build to the next.

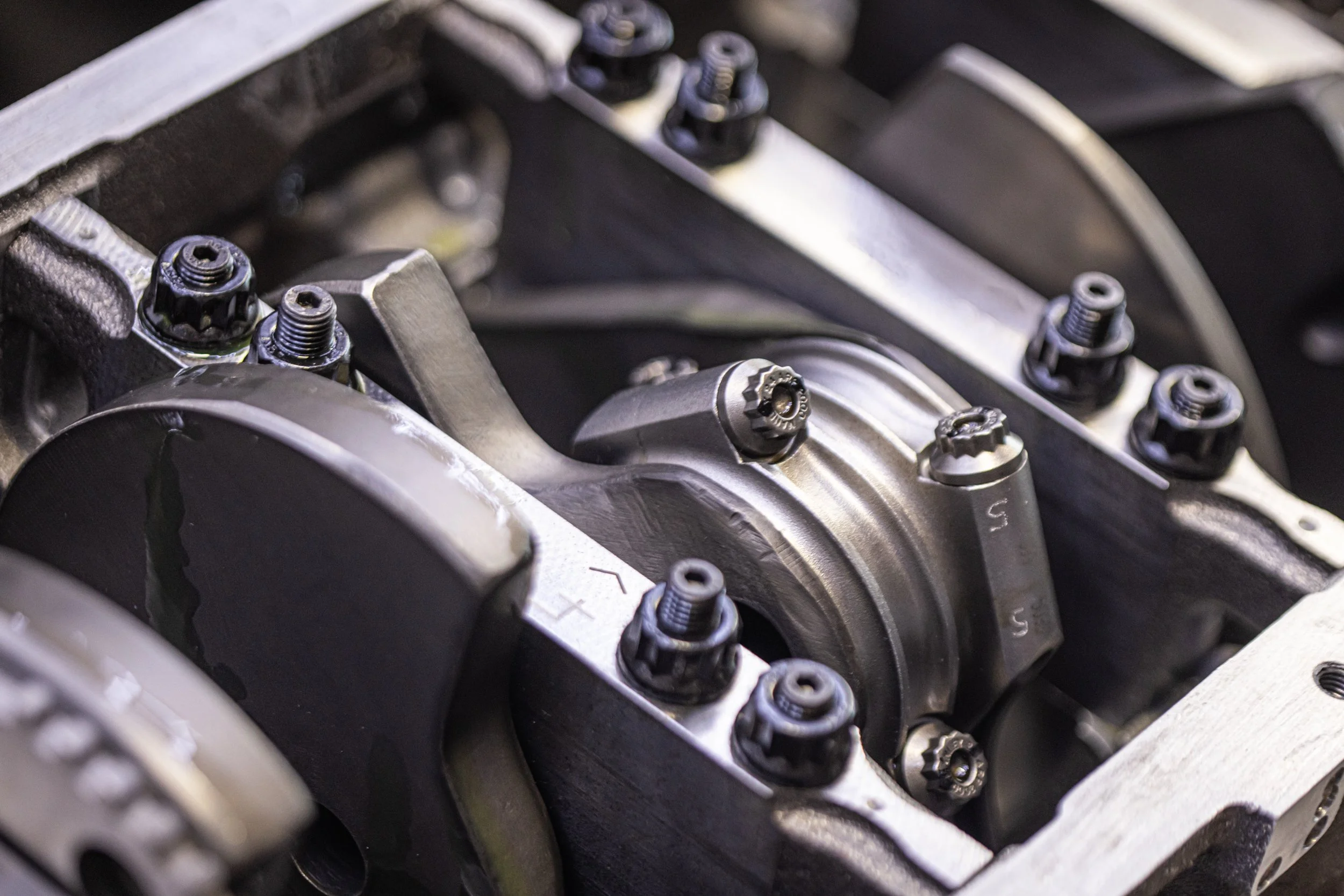

3. Studs vs. Bolts – Bottom-End Stability

Switching from bolts to studs isn’t just “race car jewelry”.

The stud stays in the block, so you’re no longer twisting fasteners in and out of the aluminum or iron threads every time you rebuild. That protects the block.

When you torque the nut, torque is applied more cleanly as preload, instead of fighting friction through the entire length of a bolt in the threads.

The main cap locates over fixed studs, which improves cap alignment and repeatability during assembly.

In practical terms, that helps:

Reduce main cap walk and fretting at the registers.

Minimize crank flex and main bore distortion at high cylinder pressures.

Preserve bearing clearances and maintain a more stable oil film at high load.

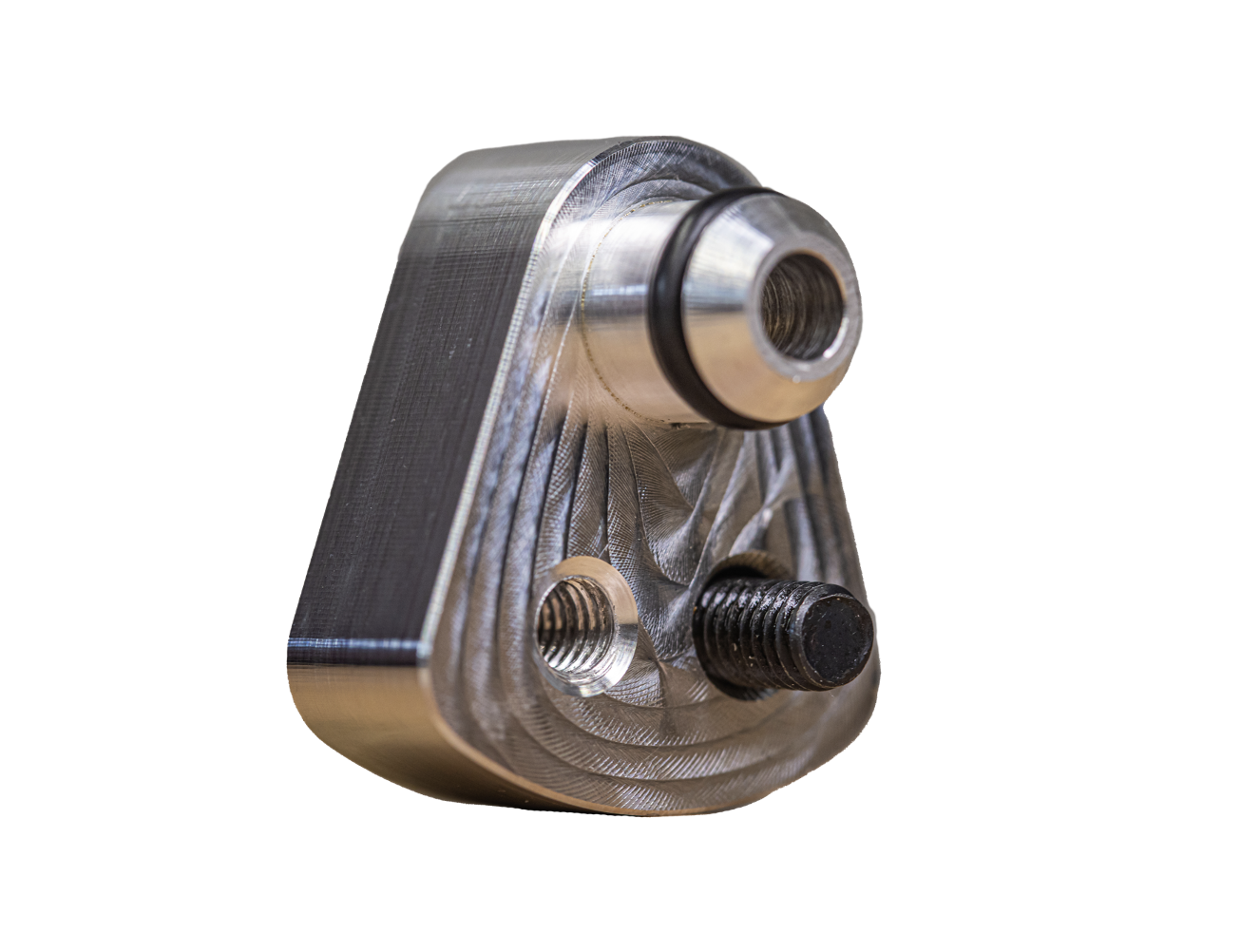

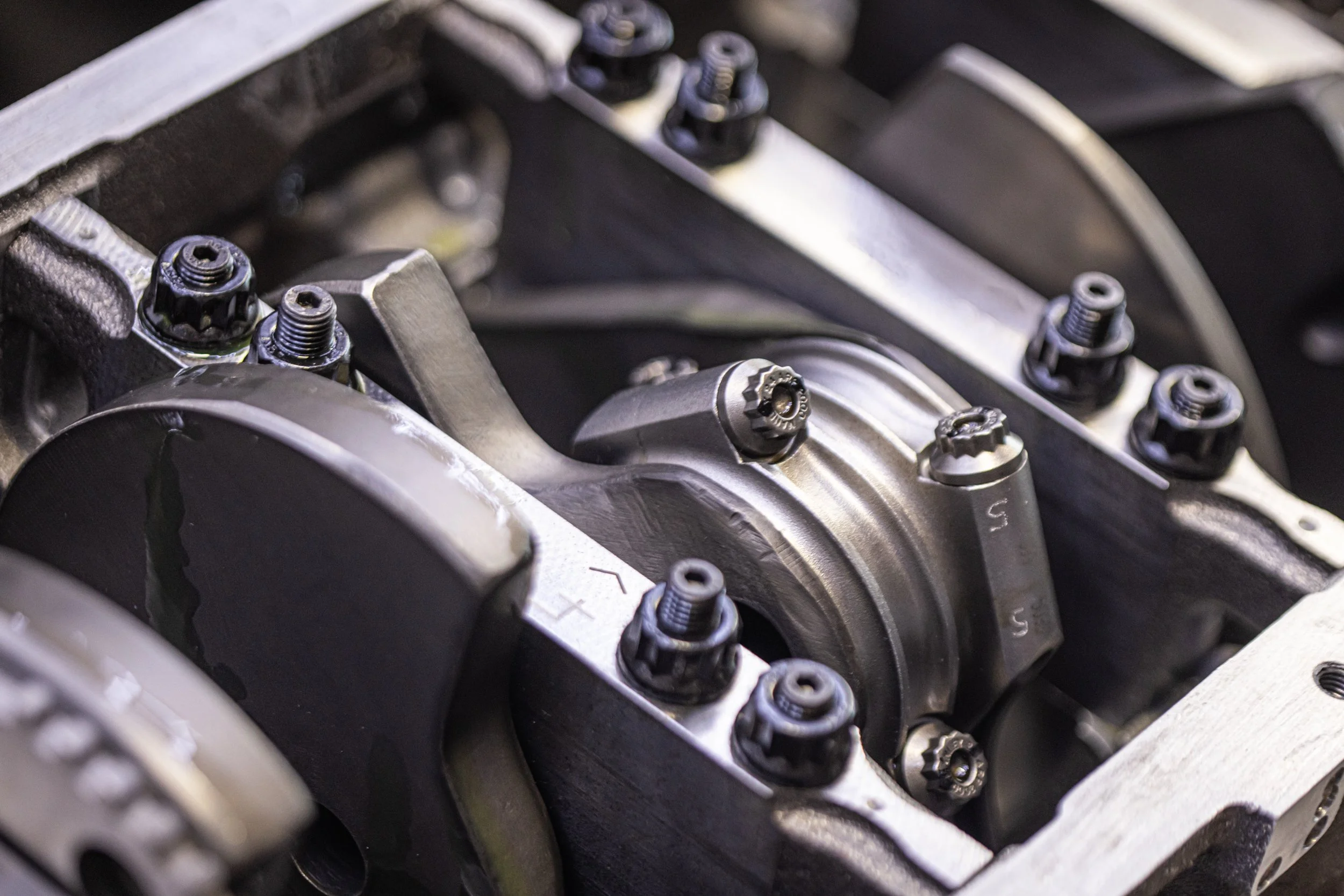

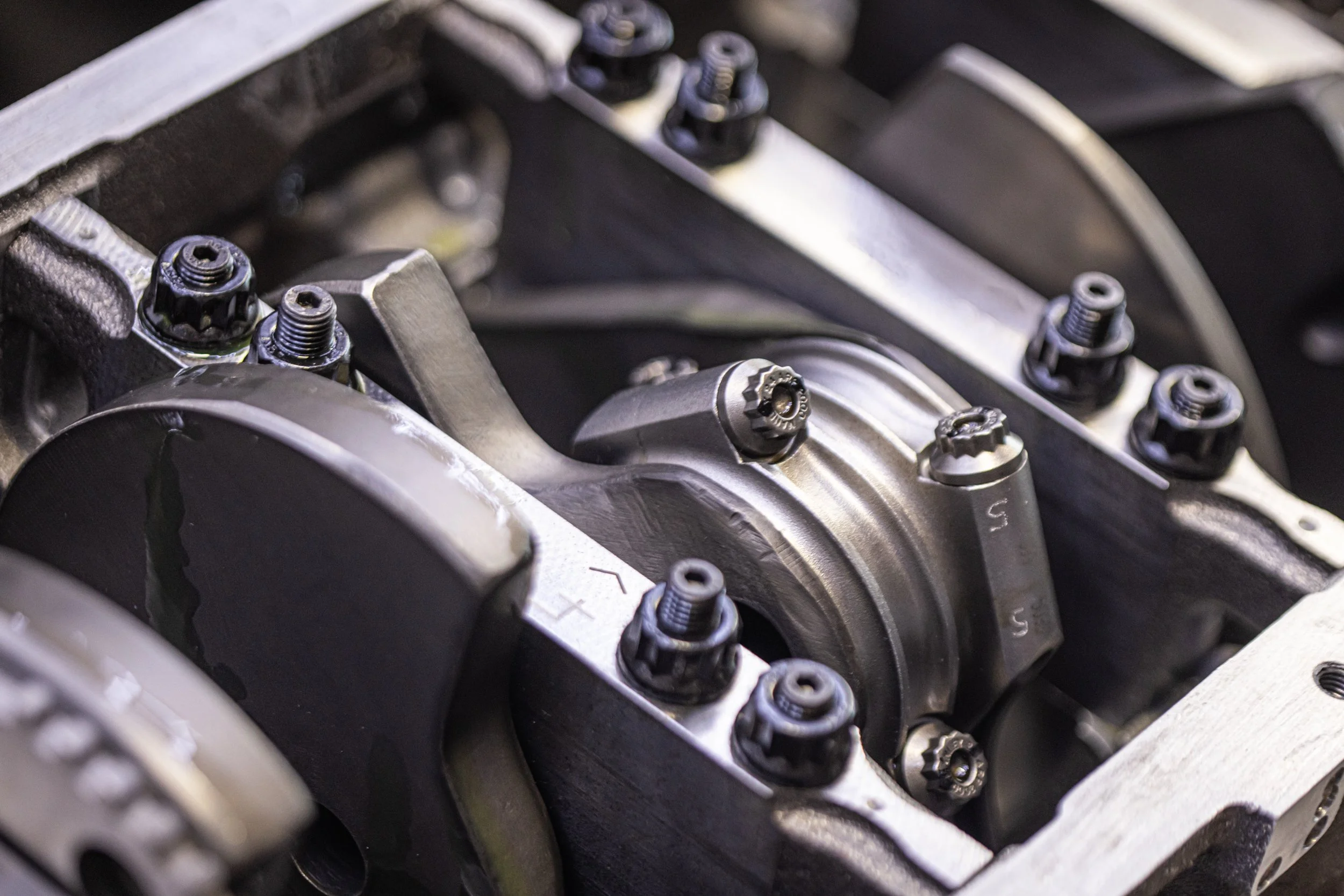

4. Complete Kit, Including Side Cross Bolts

Gen V LT mains are four-bolt designs with side cross bolts that also clamp the main caps. ARP 234-5802 includes hardware to address both:

Main cap studs

High-strength nuts

Hardened, parallel-ground washers

Side cross bolts

The hardened washers spread load evenly across the cap surface, minimizing localized distortion and helping maintain round main bores at torque.

5. Quality & Serviceability

Black oxide finish for corrosion resistance and easy inspection.

Socket sizes: 10mm 12-point, 16mm 12-point, with a 4mm Allen provision in the studs for installation.

Designed to be used with ARP Ultra-Torque lube and their published torque specs to achieve more consistent, predictable clamping force across the main saddles.

Real-World Benefits on a Built LT

More stable crankshaft geometry

With higher, more consistent clamping, the crankshaft is less likely to flex and move around at high load, which helps:

Maintain bearing alignment and longevity

Improve ring seal by reducing bore distortion at the bottom end

Keep oil film stability more consistent during transient load and high RPM

Less cap walk & fretting

Main cap “walk” and fretting are subtle at first but show up in teardown as shiny or pitted registers and chewed-up bearing shells. Locking the caps down with ARP studs and cross bolts dramatically reduces that, especially on engines that see repeated hard launches, drag radials/slicks, or long track sessions.

Better data, cleaner tuning, more repeatable power

A more stable bottom end helps your tune hold up as you push the combo harder:

Less crank flex → more consistent trigger and crank signal

More consistent main bore geometry → more predictable oil pressure and bearing temps

Stronger foundation for high boost, E-fuel, and high RPM without “mystery” bearing failures

This is the kind of part you never notice when it works—which is exactly the point.

Fitment Guide – Gen V LT Engines

From ARP and multiple LT-focused distributors, 234-5802 is specified to fit 2014+ GM Gen V LT-based 5.3L & 6.2L V8 engines, including both car and truck/SUV variants.

Engines:

*5.3L: L82, L83, L84

*6.2L: LT1, LT2, LT4, L86, L87

*6.6L: L8T (gas HD)

Common Vehicle Applications (2014+):

Cars:

* 2014–2019 Corvette C7 Stingray / Grand Sport (LT1)

* 2015–2019 Corvette C7 Z06 (LT4)

* 2020+ Corvette C8 (LT2)

* 2016–2024 Camaro SS & LT1 (LT1)

* 2017–2024 Camaro ZL1 (LT4)

* Other Gen V LT-powered GM performance cars using LT1/LT4/LT2 blocks

Trucks & SUVs:

* 2014–present Silverado 1500 / Sierra 1500 (L82/L83/L84/L86/L87)

* 2015–present Tahoe / Suburban / Yukon / Yukon XL (5.3L & 6.2L Gen V)

* 2015–present Cadillac Escalade (6.2L Gen V)

* 2020+ Silverado / Sierra HD with 6.6L L8T gas V8

If you’re already in the short block, this is the time to upgrade the main hardware. For the cost of a few dyno pulls, you get a much stronger foundation for the power you’re chasing.

ARP Pro Series Main Stud Kit – Gen V LT #234-5802

When you start leaning on a Gen V LT with more boost, more RPM, more timing, and a stickier tire, the bottom end becomes the foundation that either holds it all together… or quietly ruins your season.

From the factory, Gen V LT engines use torque-to-yield main bolts that were never designed for the “all to common” 800-1,000 rwhp. The frustrating reality is that most “head and cam packages” seem to be 20k mile packages due to the lack of attention given to the factory shortblock and fasteners. As you increase cylinder pressure and load through simple “bolt ons”, those bolts can quickly reach their limit, allowing main cap “walk,” fretting of the registers, and crankshaft flex that hurts bearing life, ring seal, and oil control. Don’t believe me? I can send you photos from my 8,000 motor that already showed all of those signs making only 800rwhp (before we added more power).

The ARP 234-5802 Pro Series Main Stud Kit replaces those stressed OE fasteners with 8740 chromoly steel studs engineered for serious clamp load and long-term stability on all 2014+ Gen V LT-based 5.3L and 6.2L engines—LT1, LT4, LT2, truck L83/L86/L87 and more.

This is the main fastener kit we recommend any time an LT short block is apart for rods/pistons, stroker builds, power-adder combos, or sustained high-RPM use.

What Makes ARP 234-5802 Different?

1. Real Material Science – 8740 Chromoly, Heat Treated Hard

These studs are manufactured from 8740 chromoly steel, then heat treated to a nominal tensile strength around 190,000–200,000 psi—far beyond typical OEM main bolts and generic hardware.

8740 chromoly offers excellent fatigue resistance and high-cycle durability, crucial for a crank that’s constantly being hammered by boost and low RPM torque.

The high tensile rating allows more consistent and higher clamp load without permanent stretch, which is what keeps the caps locked to the registers instead of walking around under load.

2. Thread-Rolled After Heat Treat = Stronger Threads

ARP rolls the threads after heat treat and to Mil-S-8879-type specifications (J-form style), which dramatically increases thread fatigue strength compared to cut threads or rolled-before-heat-treat designs.

That matters because:

Threads become the first stress concentration when things get ugly.

Stronger threads mean the fastener is far less likely to fail at the root, even with repeated teardowns and retorques.

Along with precision centerless grinding, this gives you a stud that provides highly repeatable clamping force from one build to the next.

3. Studs vs. Bolts – Bottom-End Stability

Switching from bolts to studs isn’t just “race car jewelry”.

The stud stays in the block, so you’re no longer twisting fasteners in and out of the aluminum or iron threads every time you rebuild. That protects the block.

When you torque the nut, torque is applied more cleanly as preload, instead of fighting friction through the entire length of a bolt in the threads.

The main cap locates over fixed studs, which improves cap alignment and repeatability during assembly.

In practical terms, that helps:

Reduce main cap walk and fretting at the registers.

Minimize crank flex and main bore distortion at high cylinder pressures.

Preserve bearing clearances and maintain a more stable oil film at high load.

4. Complete Kit, Including Side Cross Bolts

Gen V LT mains are four-bolt designs with side cross bolts that also clamp the main caps. ARP 234-5802 includes hardware to address both:

Main cap studs

High-strength nuts

Hardened, parallel-ground washers

Side cross bolts

The hardened washers spread load evenly across the cap surface, minimizing localized distortion and helping maintain round main bores at torque.

5. Quality & Serviceability

Black oxide finish for corrosion resistance and easy inspection.

Socket sizes: 10mm 12-point, 16mm 12-point, with a 4mm Allen provision in the studs for installation.

Designed to be used with ARP Ultra-Torque lube and their published torque specs to achieve more consistent, predictable clamping force across the main saddles.

Real-World Benefits on a Built LT

More stable crankshaft geometry

With higher, more consistent clamping, the crankshaft is less likely to flex and move around at high load, which helps:

Maintain bearing alignment and longevity

Improve ring seal by reducing bore distortion at the bottom end

Keep oil film stability more consistent during transient load and high RPM

Less cap walk & fretting

Main cap “walk” and fretting are subtle at first but show up in teardown as shiny or pitted registers and chewed-up bearing shells. Locking the caps down with ARP studs and cross bolts dramatically reduces that, especially on engines that see repeated hard launches, drag radials/slicks, or long track sessions.

Better data, cleaner tuning, more repeatable power

A more stable bottom end helps your tune hold up as you push the combo harder:

Less crank flex → more consistent trigger and crank signal

More consistent main bore geometry → more predictable oil pressure and bearing temps

Stronger foundation for high boost, E-fuel, and high RPM without “mystery” bearing failures

This is the kind of part you never notice when it works—which is exactly the point.

Fitment Guide – Gen V LT Engines

From ARP and multiple LT-focused distributors, 234-5802 is specified to fit 2014+ GM Gen V LT-based 5.3L & 6.2L V8 engines, including both car and truck/SUV variants.

Engines:

*5.3L: L82, L83, L84

*6.2L: LT1, LT2, LT4, L86, L87

*6.6L: L8T (gas HD)

Common Vehicle Applications (2014+):

Cars:

* 2014–2019 Corvette C7 Stingray / Grand Sport (LT1)

* 2015–2019 Corvette C7 Z06 (LT4)

* 2020+ Corvette C8 (LT2)

* 2016–2024 Camaro SS & LT1 (LT1)

* 2017–2024 Camaro ZL1 (LT4)

* Other Gen V LT-powered GM performance cars using LT1/LT4/LT2 blocks

Trucks & SUVs:

* 2014–present Silverado 1500 / Sierra 1500 (L82/L83/L84/L86/L87)

* 2015–present Tahoe / Suburban / Yukon / Yukon XL (5.3L & 6.2L Gen V)

* 2015–present Cadillac Escalade (6.2L Gen V)

* 2020+ Silverado / Sierra HD with 6.6L L8T gas V8

If you’re already in the short block, this is the time to upgrade the main hardware. For the cost of a few dyno pulls, you get a much stronger foundation for the power you’re chasing.