Image 1 of 17

Image 1 of 17

Image 2 of 17

Image 2 of 17

Image 3 of 17

Image 3 of 17

Image 4 of 17

Image 4 of 17

Image 5 of 17

Image 5 of 17

Image 6 of 17

Image 6 of 17

Image 7 of 17

Image 7 of 17

Image 8 of 17

Image 8 of 17

Image 9 of 17

Image 9 of 17

Image 10 of 17

Image 10 of 17

Image 11 of 17

Image 11 of 17

Image 12 of 17

Image 12 of 17

Image 13 of 17

Image 13 of 17

Image 14 of 17

Image 14 of 17

Image 15 of 17

Image 15 of 17

Image 16 of 17

Image 16 of 17

Image 17 of 17

Image 17 of 17

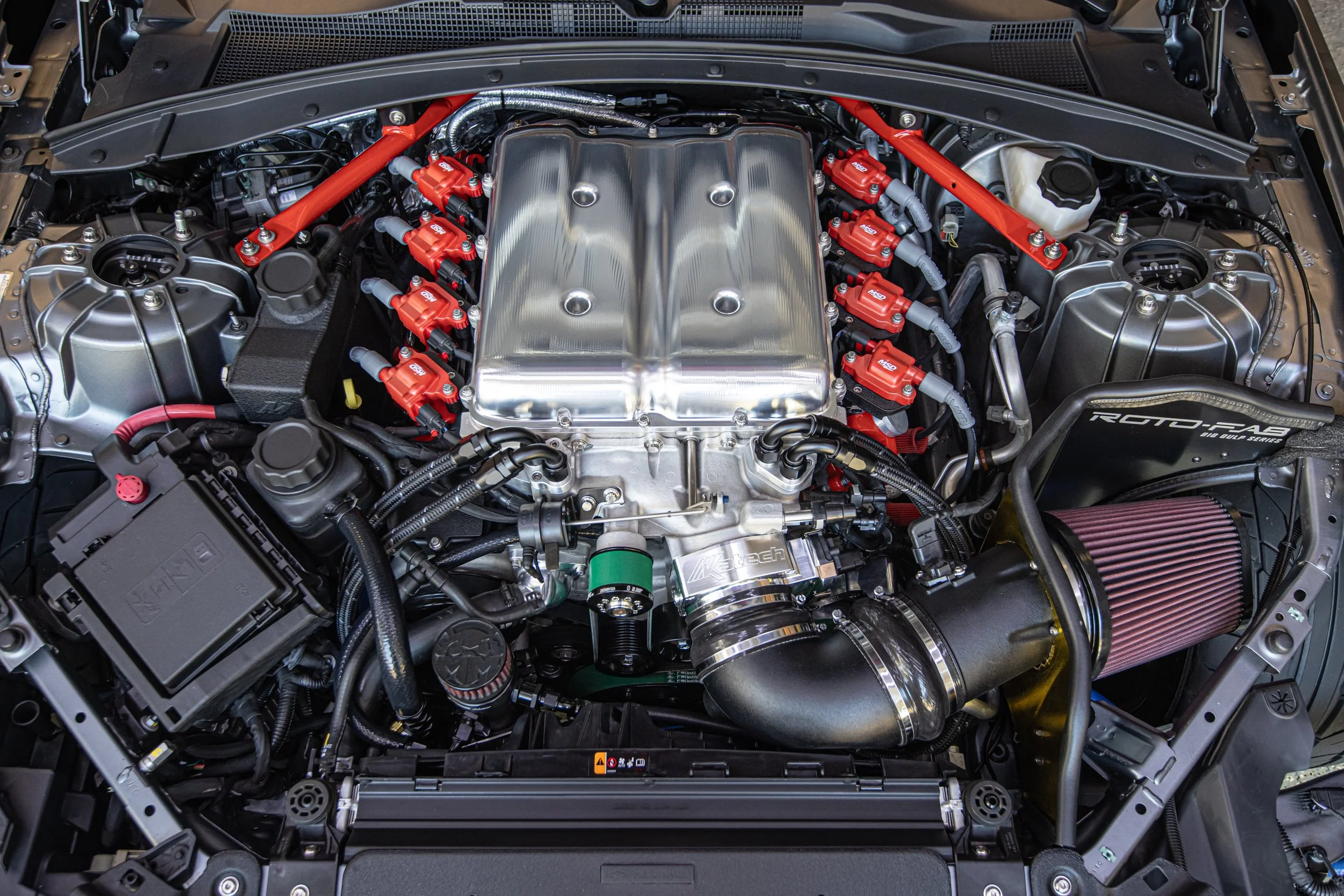

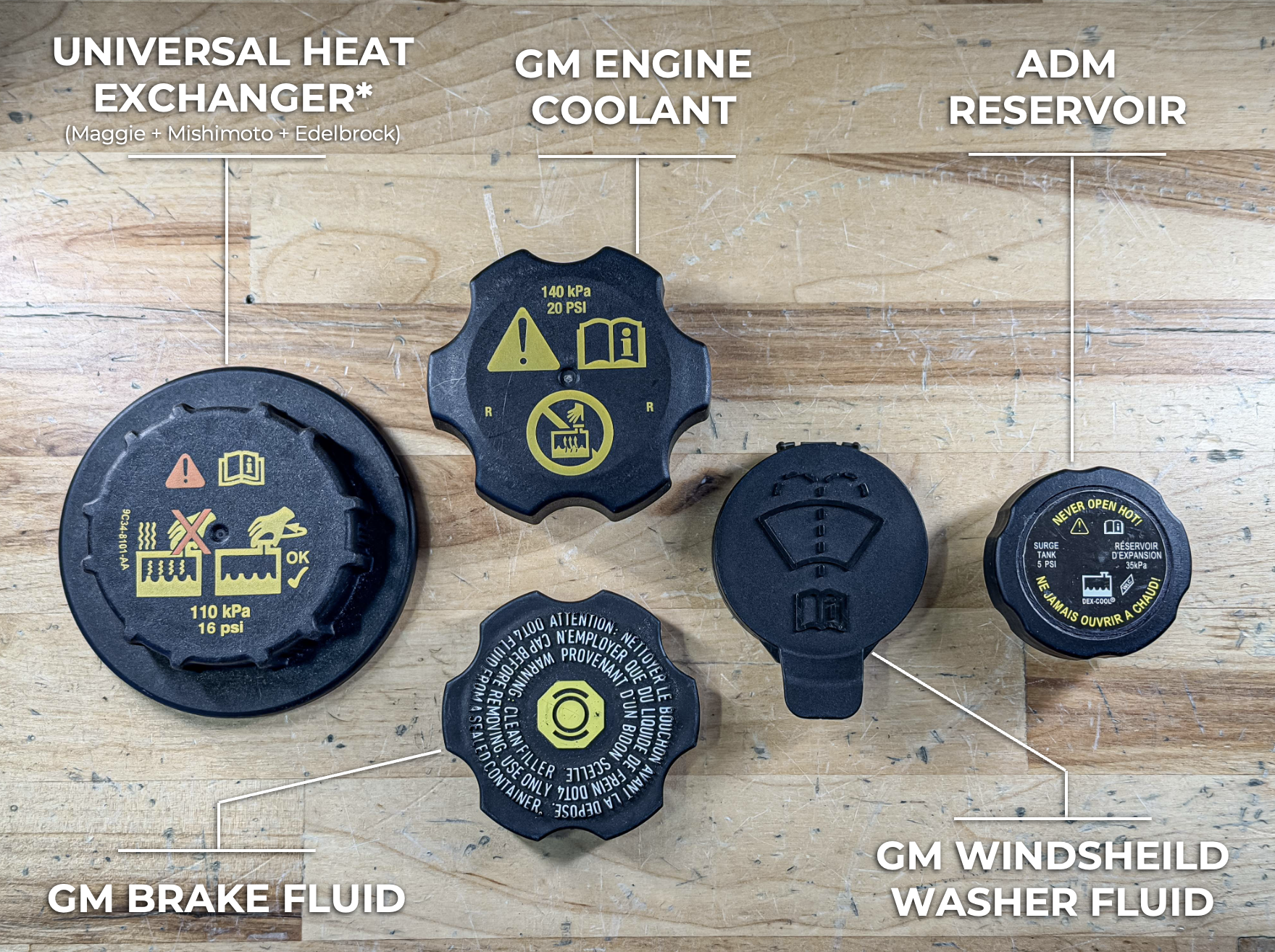

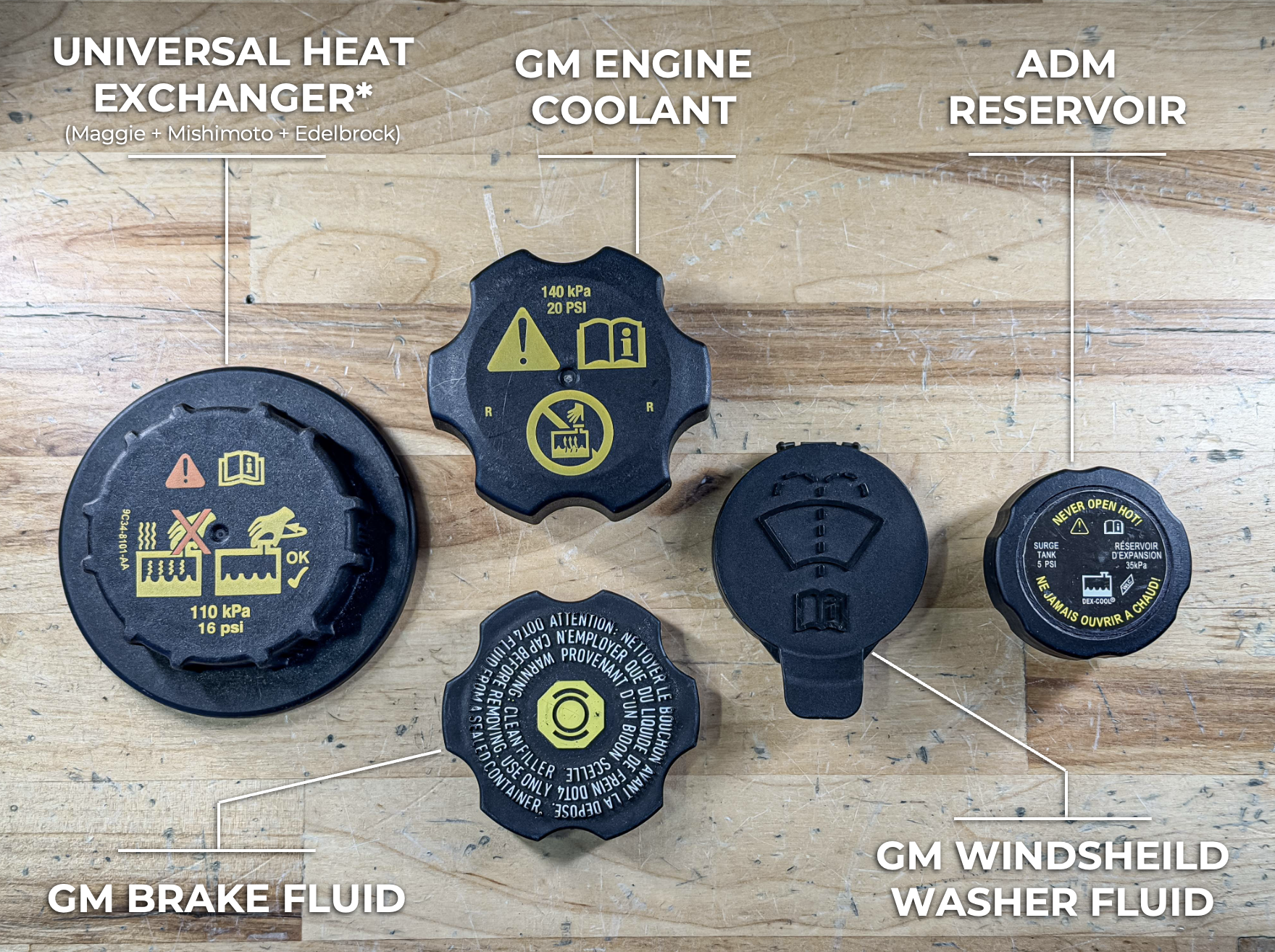

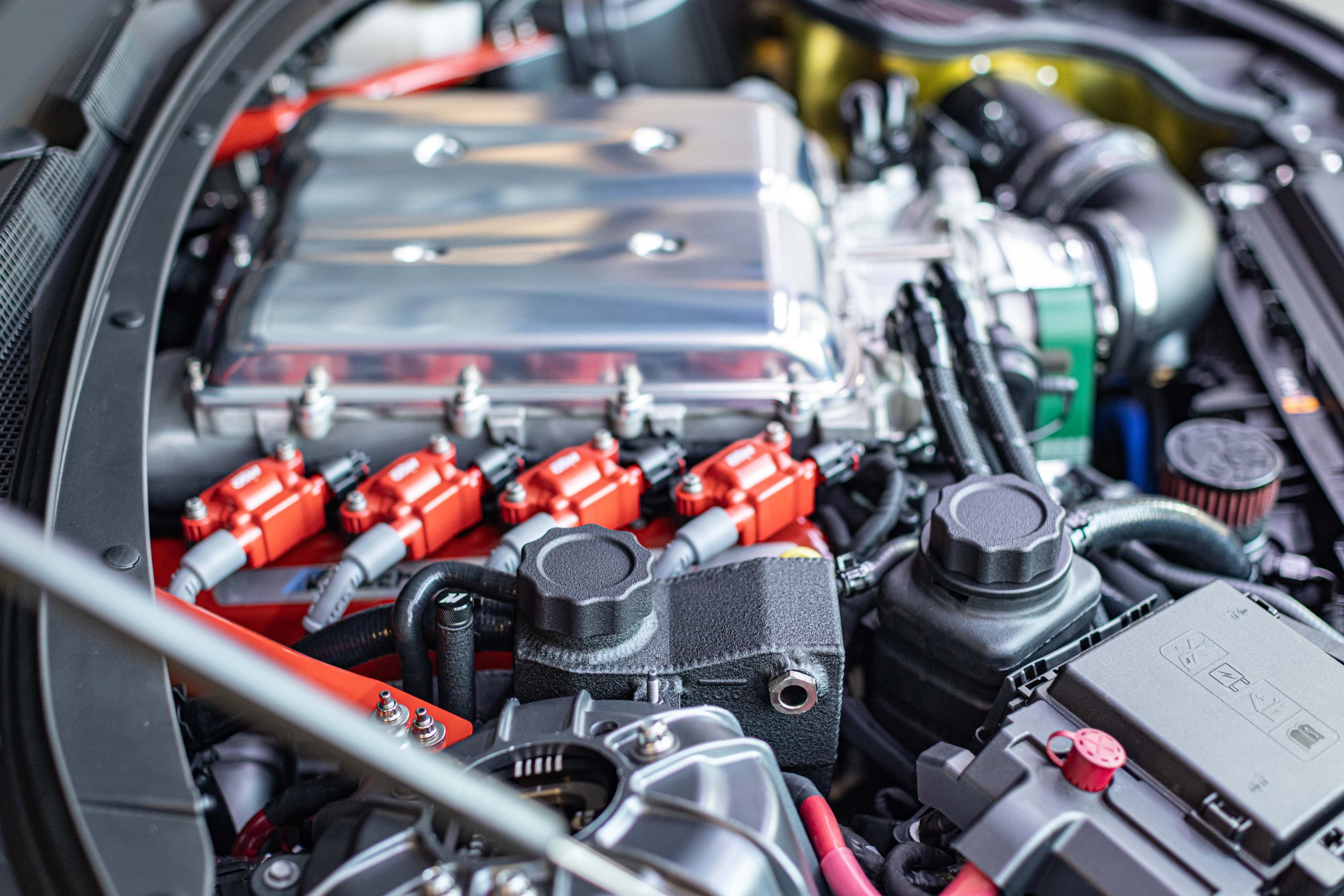

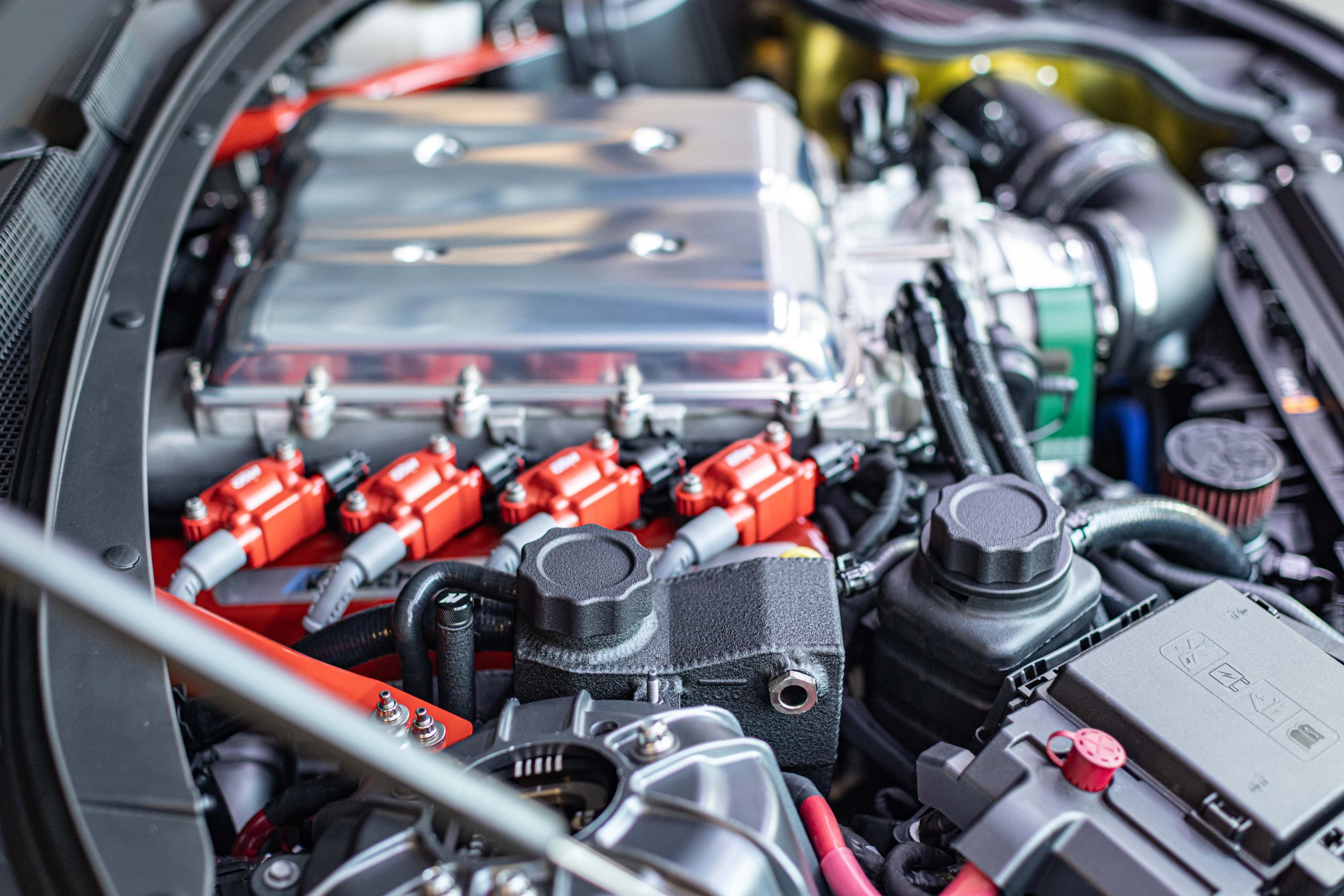

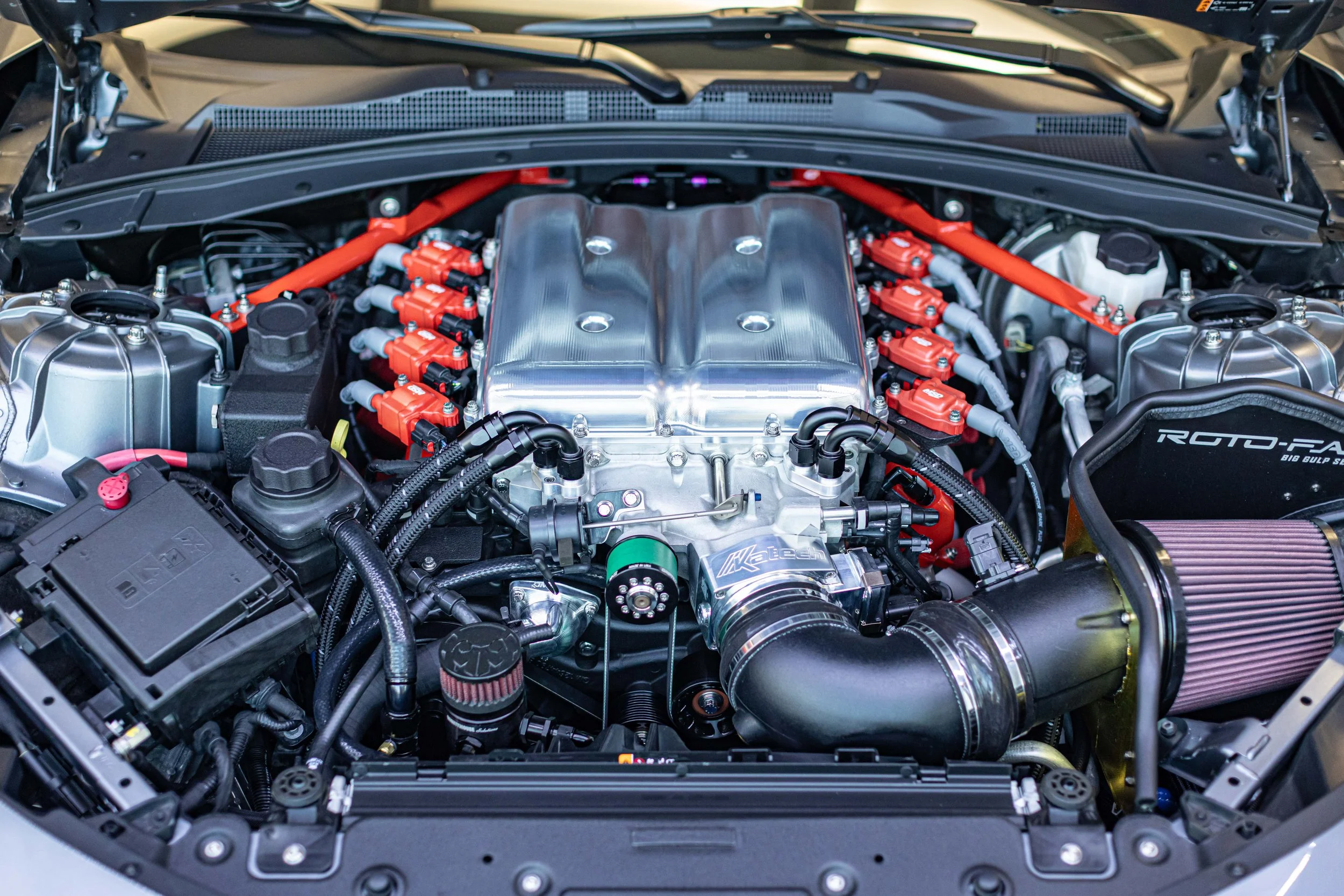

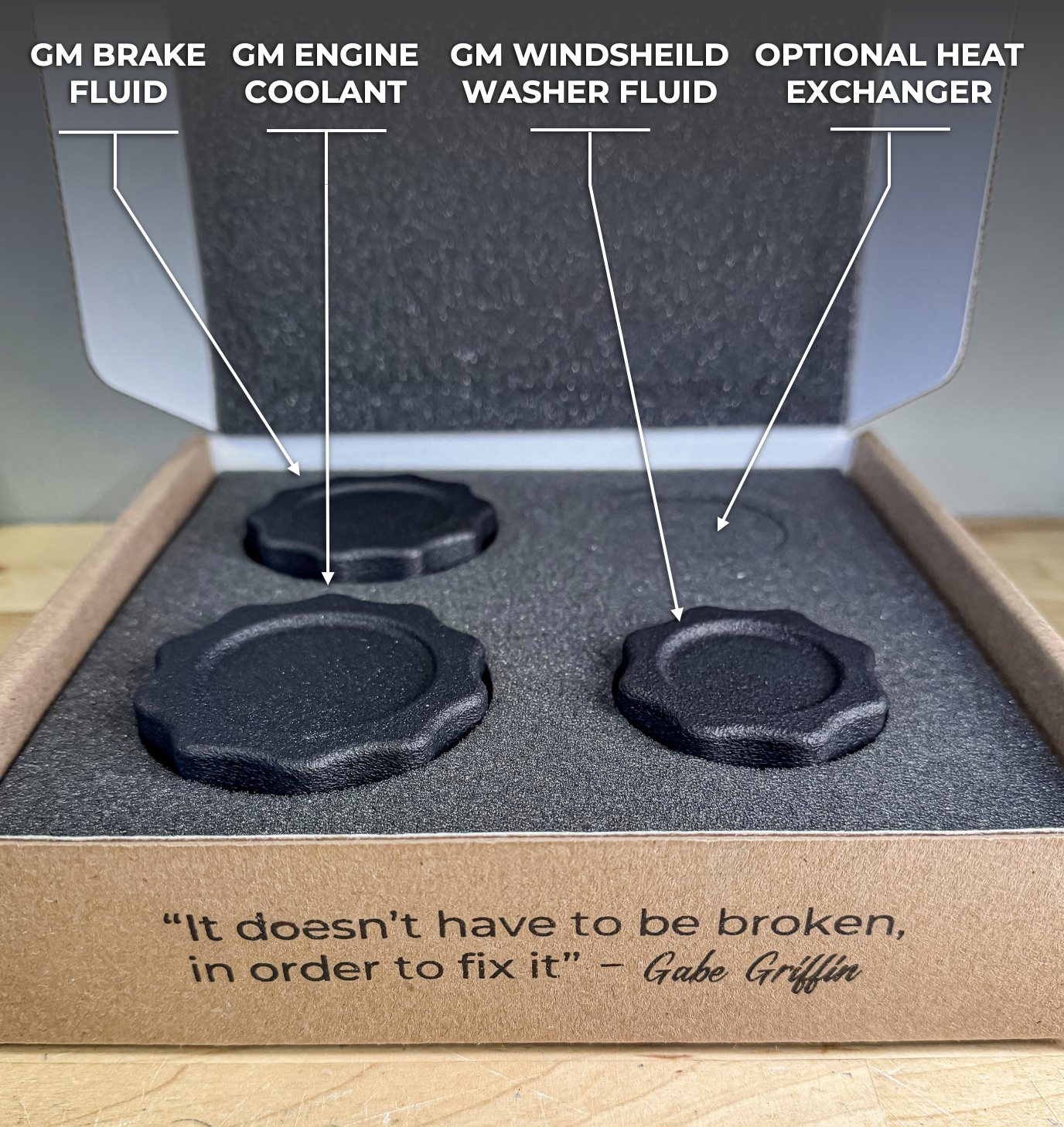

6th Gen Camaro Decorative Reservoir Caps

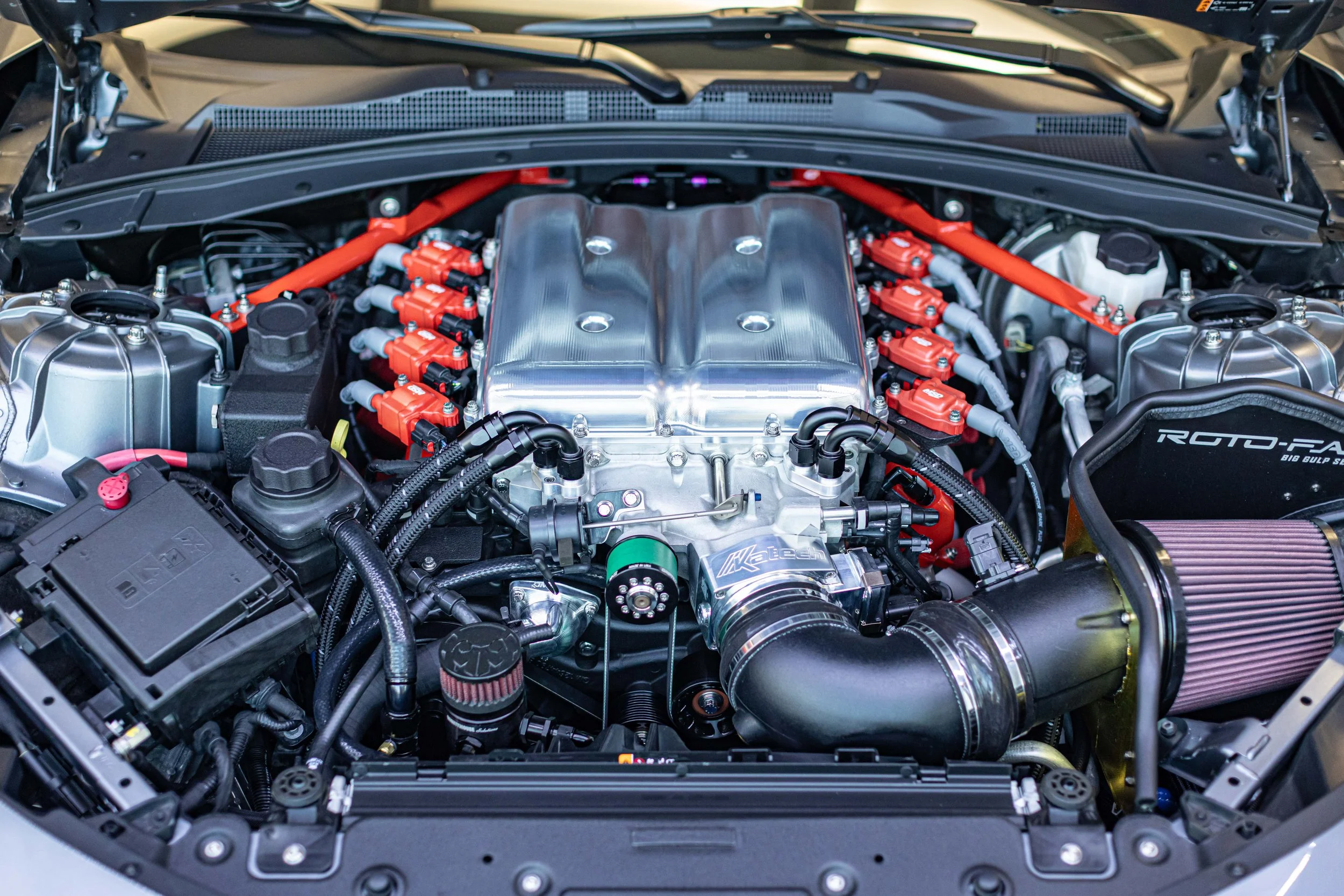

Stand out. Without being a standout.

Because not every upgrade needs to add horsepower.

If you are like me, you want your engine bay to look as good, as your car runs. You care about the small details, and have tremendous pride of ownership.

This is why we set out to create a cost effective “non-flashy” way to cover the ugly OEM reservoir caps with a clean, tasteful design that “covers the mess” and allows the rest of your build to stand out and shine.

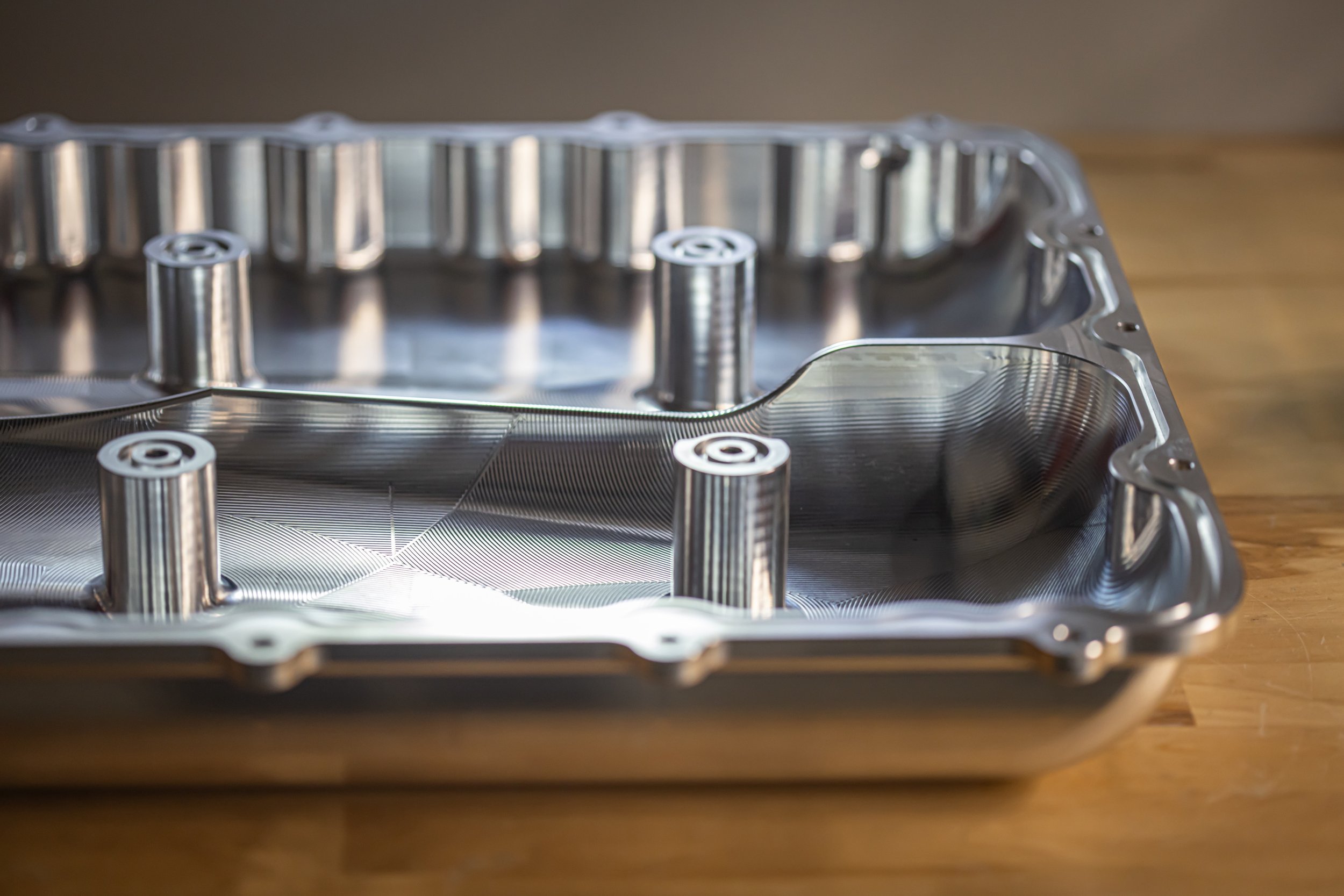

These decorative reservoir caps are designed for the enthusiast who understands that a well-sorted engine bay should look as refined as it performs. Manufactured using ultra-durable PA12 nylon on an industrial-grade SLS (Selective Laser Sintering) printer, these caps deliver OEM-plus aesthetics with modern manufacturing precision.

Each cap was designed in 3D and carefully printed on a $500,000 industrial HP SLS system, allowing for extremely tight tolerances, uniform wall thickness, and exceptional surface consistency. The result is a part that feels intentional—not 3D printed in the hobbyist sense, but engineered and finished to a professional standard.

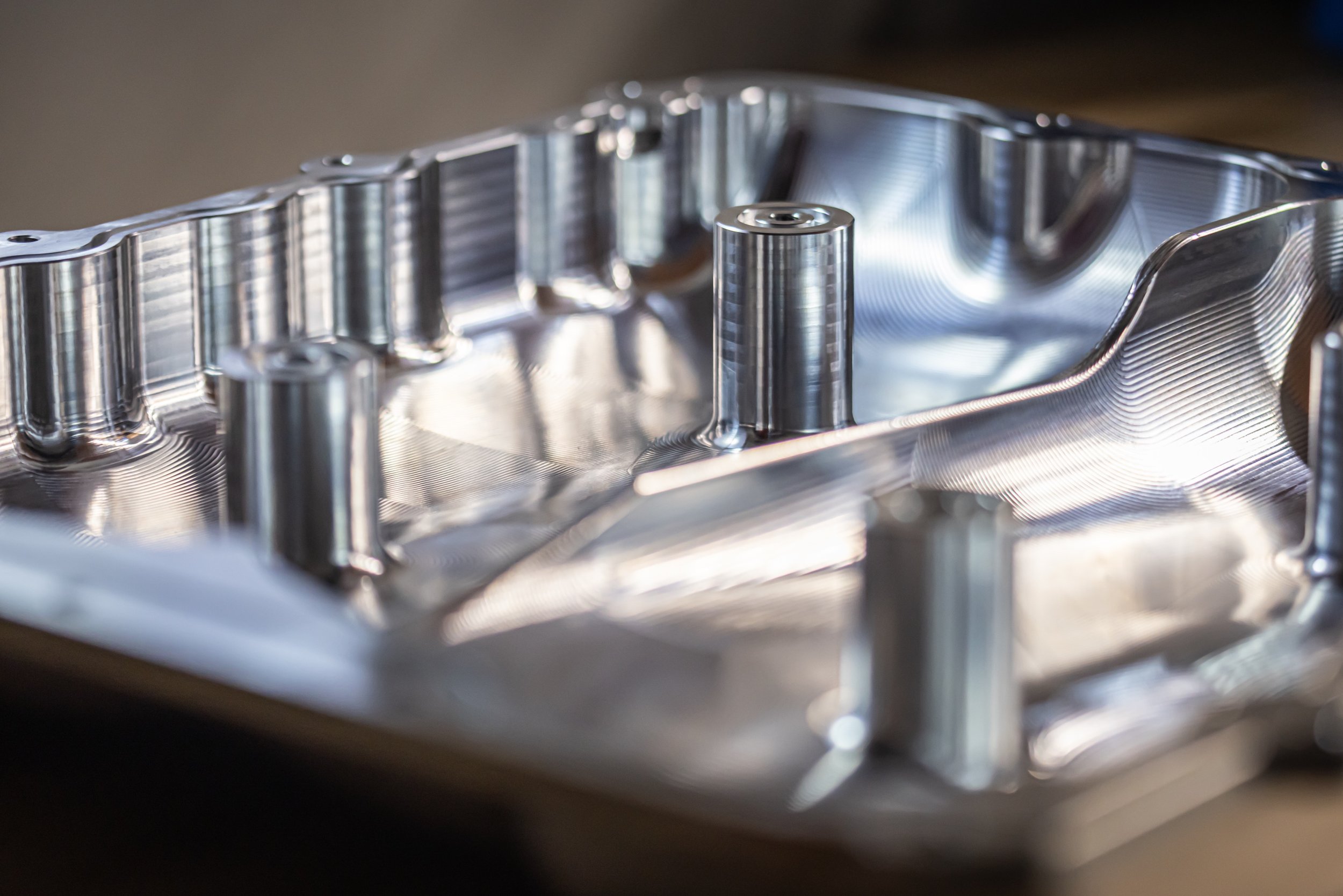

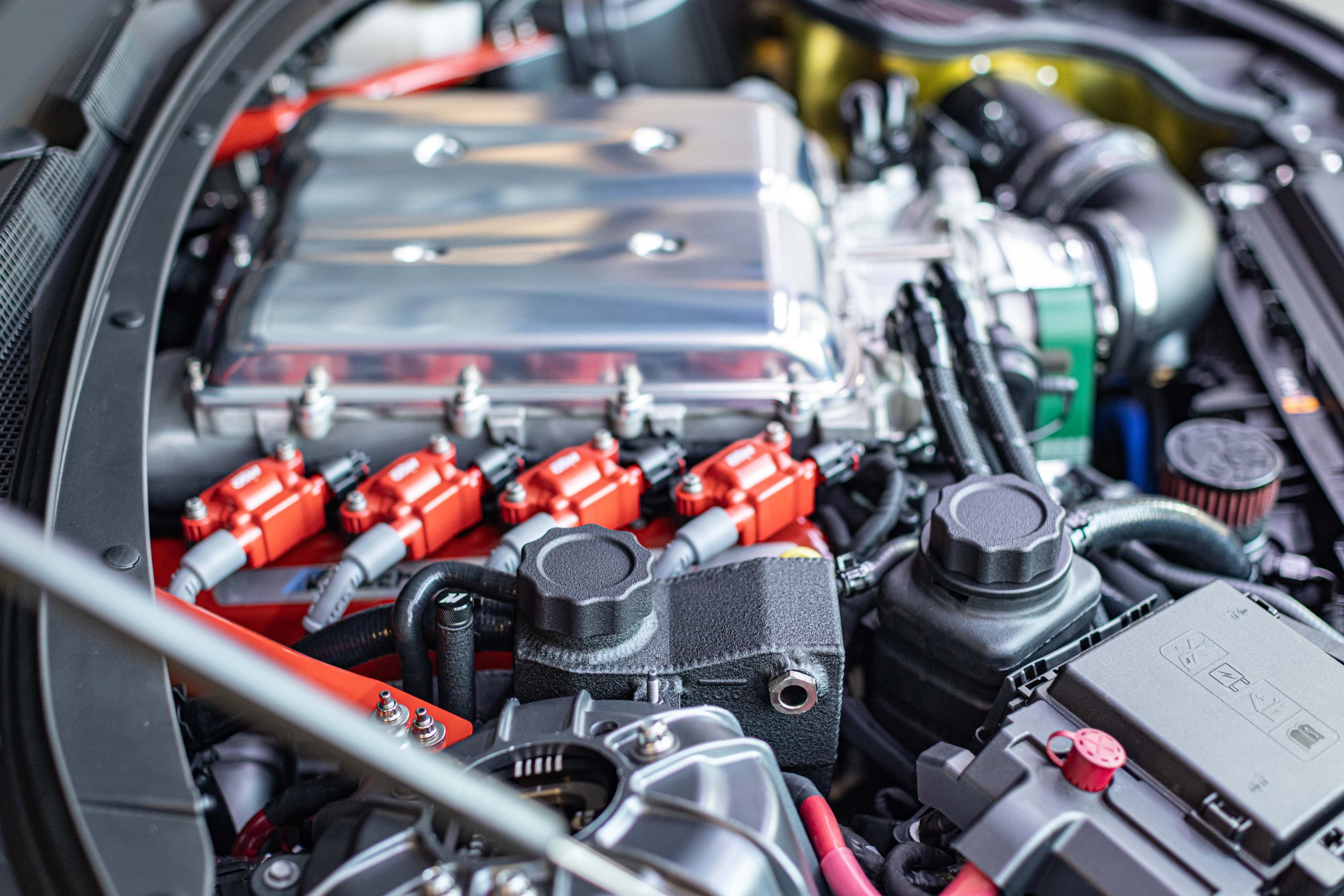

Material & Durability – Why PA12 Nylon Matters

For those who don’t know, PA12 (Polyamide 12) nylon is a material widely used in OEM automotive components, aerospace ducting, and motorsports applications due to its excellent balance of strength, flexibility, and thermal stability.

Compared to lower-grade plastics or hobby-level 3D printing materials, PA12 offers:

High heat resistance, making it well-suited for under-hood environments

Excellent chemical resistance to oils, coolants, and common automotive fluids

Dimensional stability, ensuring consistent fitment over time

Impact and fatigue resistance, so the caps won’t become brittle or crack with age

Because these parts are produced using industrial SLS printing, they are fully dense and isotropic—meaning strength is consistent in all directions, unlike layered filament prints that can delaminate or warp over time.

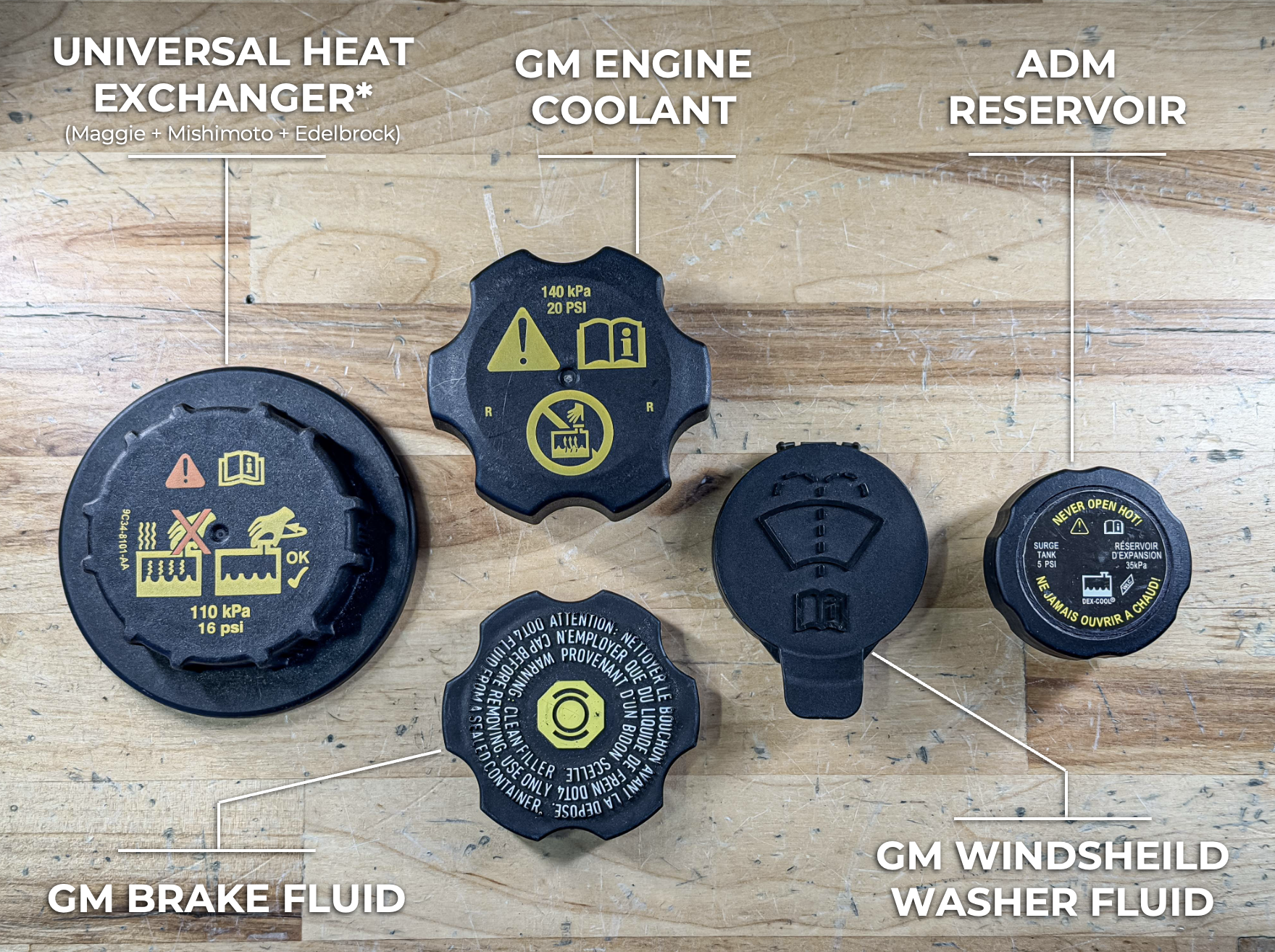

The surface is printed with a satin-wrinkle texture, carefully chosen to mimic the look of our GMS High Flow Hood Brackets that utilize a satin black wrinkle powder coating. After printing, each cap is dyed black, creating a deep, uniform finish that resists fading and blends seamlessly into both factory and modified engine bays. The satin-wrinkle texture isn’t just cosmetic—it also helps mask fingerprints, dust, and minor wear, keeping the engine bay looking clean and intentional.

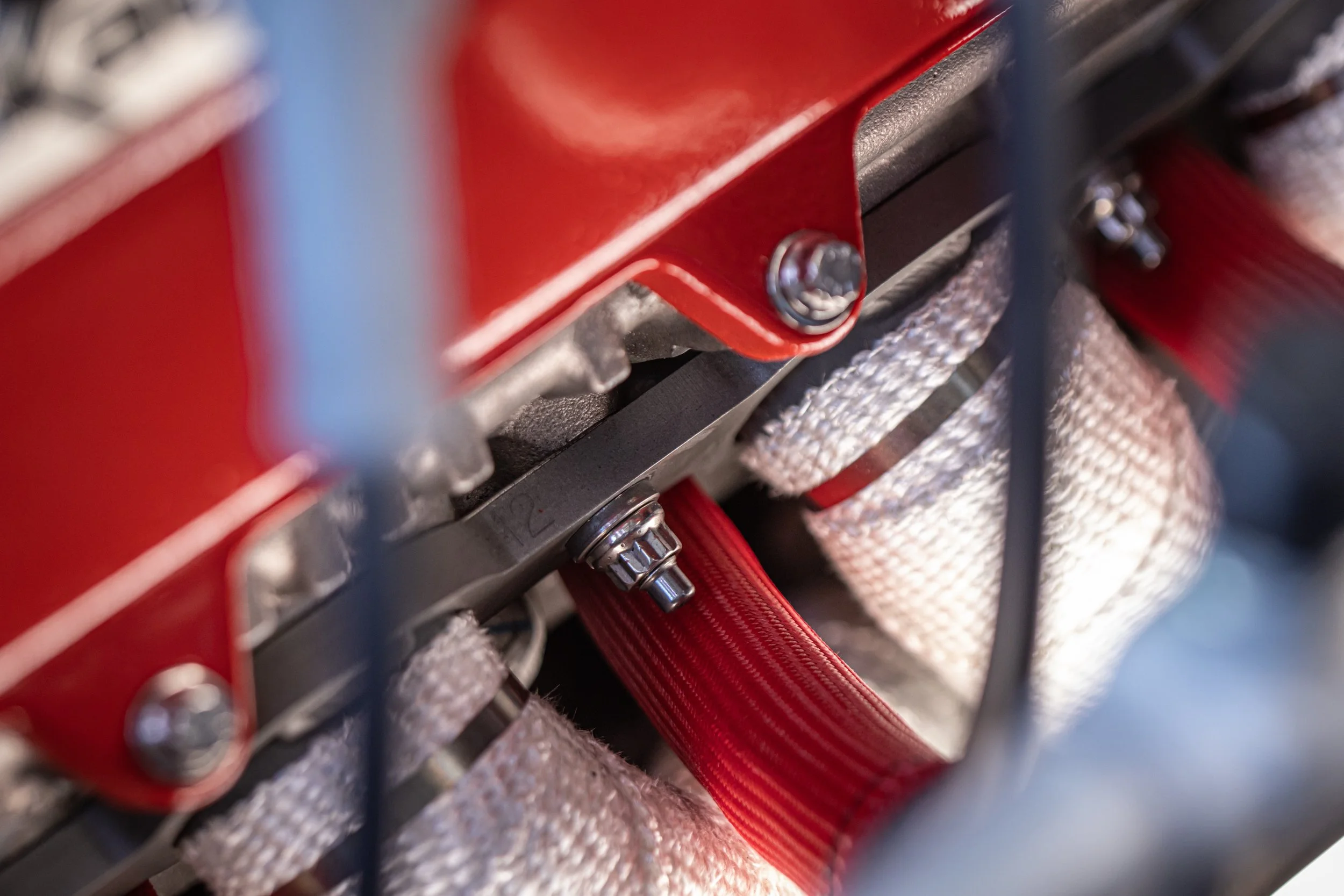

Installation is not only simple, but fully reversible. These caps install directly over your existing factory reservoir caps using a precise friction fit (no adhesives, no hardware, and no permanent modifications) They stay secure in normal driving conditions while allowing easy removal if needed. (note: due to the some slight variation in reservoir cap dimensions, a dab of RTV or silicone may be needed to secure the fitment)

Let’s be clear: these caps are purely cosmetic. They don’t change performance, pressure, or function—and that’s exactly the point. They exist for drivers who open the hood and care about what they see. For those who believe a car that runs hard should also look the part.

Because performance is expected—details are chosen.

Who These Are For…

Enthusiasts who value engine bay aesthetics

Owners building a clean, OEM-plus or show-quality look

Drivers who believe the details matter just as much as the dyno sheet

If you care about what your car looks like when the hood is open—or when the photos get posted—this is the finishing touch.

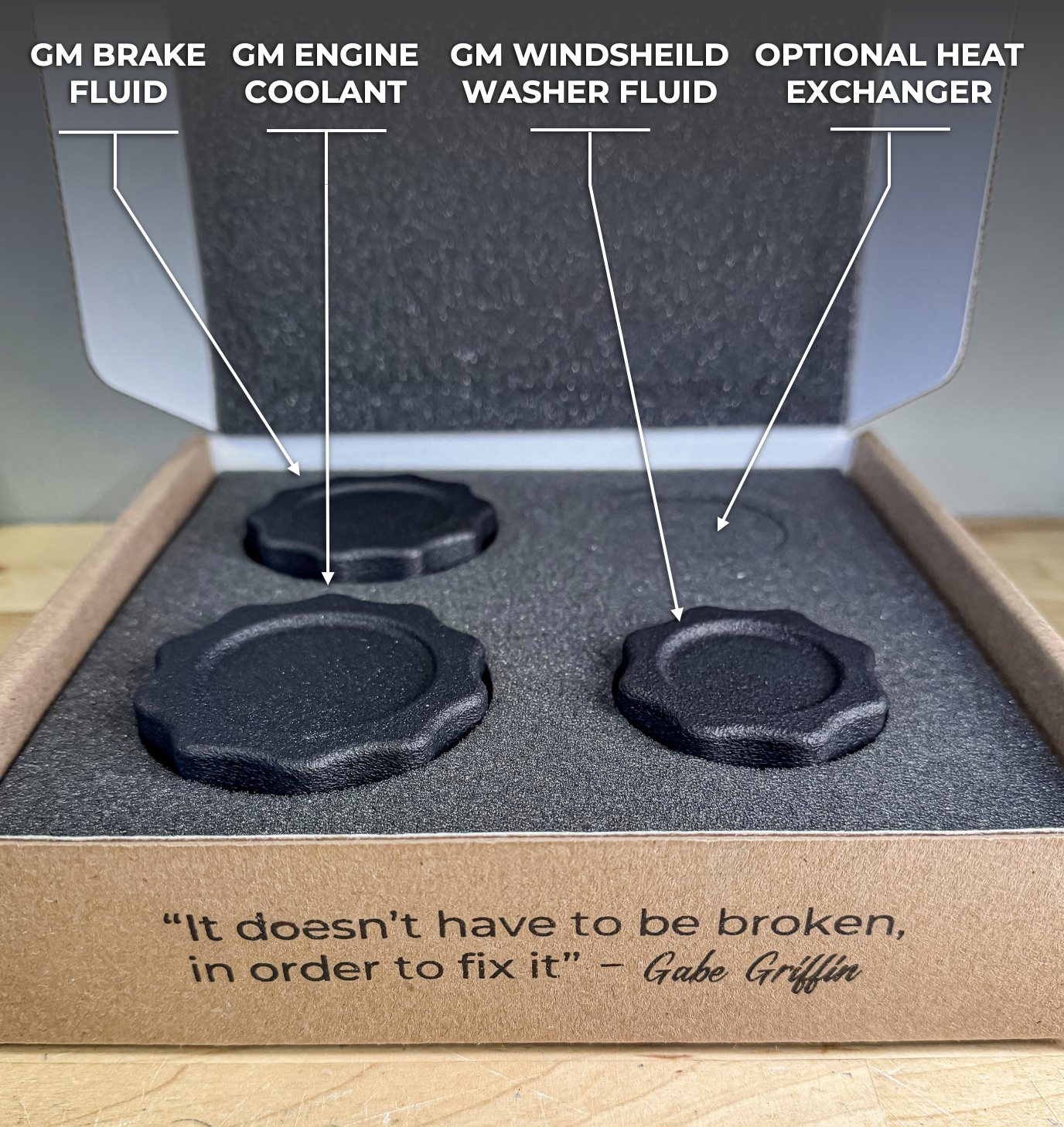

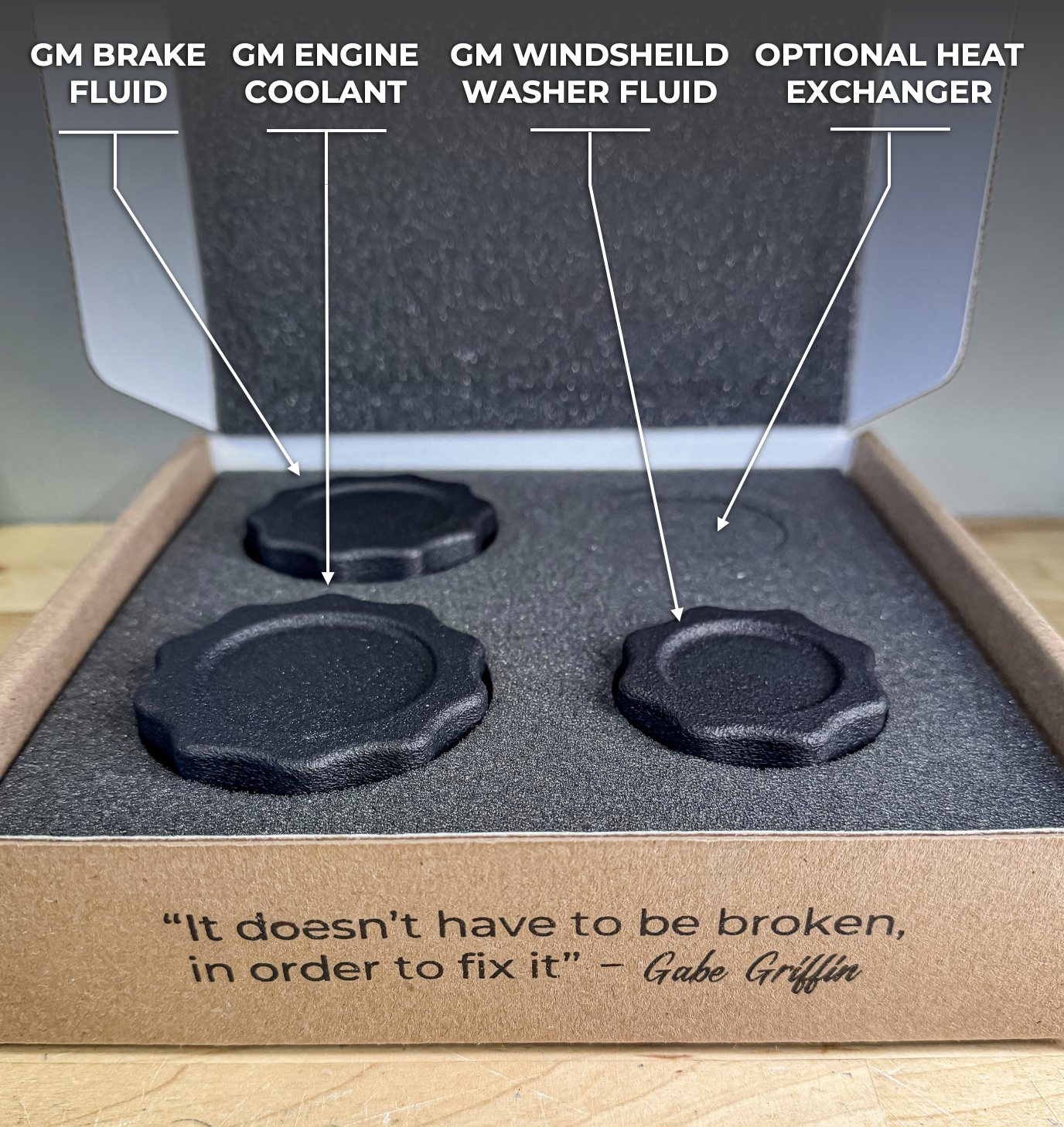

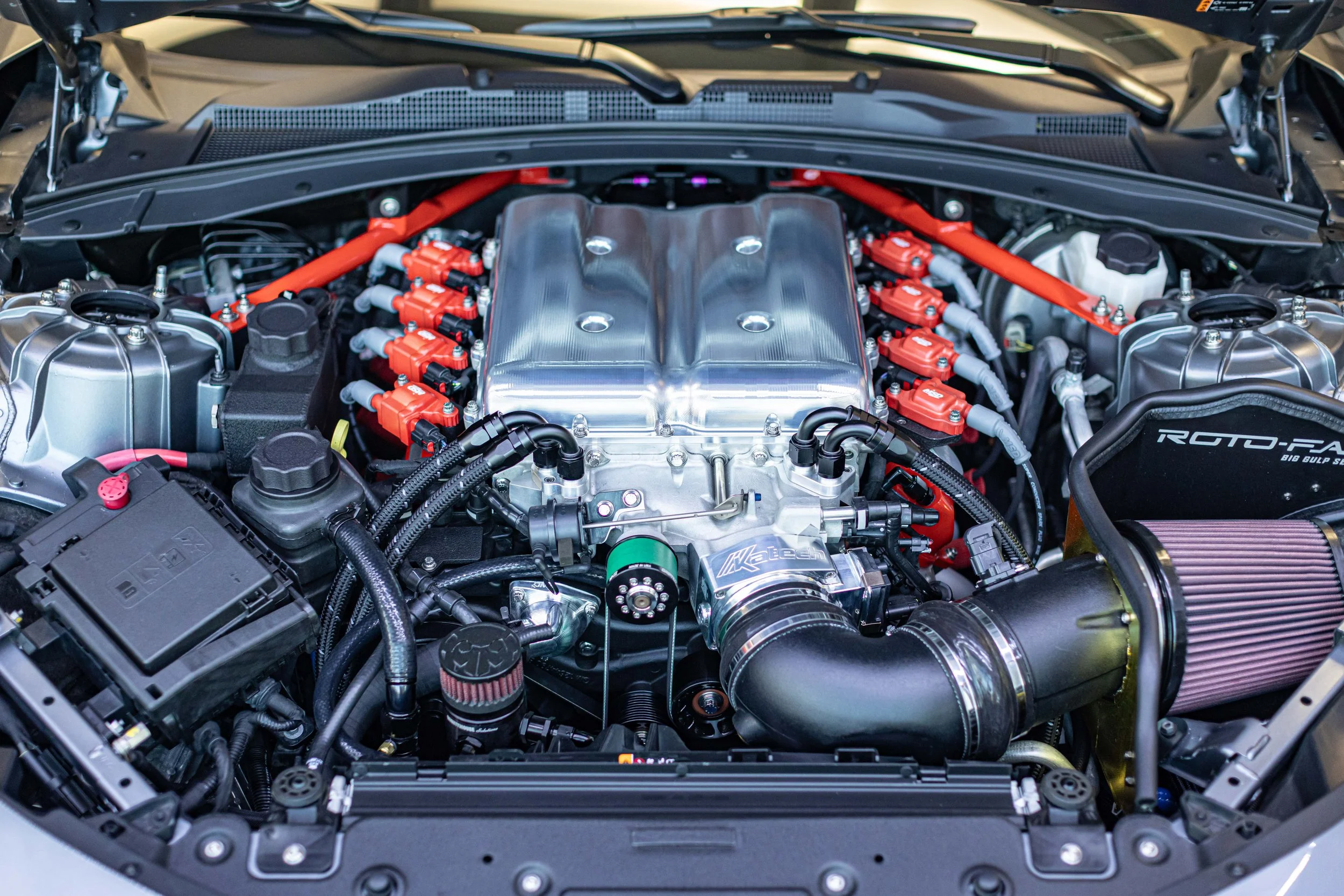

What’s in the box:

(1) Engine Coolant Reservoir Cap

(1) Windshield Washer Filler Cap

(1) Brake Fluid Reservoir Cap

(option heat exchanger cap if selected in the pull downs)

Stand out. Without being a standout.

Because not every upgrade needs to add horsepower.

If you are like me, you want your engine bay to look as good, as your car runs. You care about the small details, and have tremendous pride of ownership.

This is why we set out to create a cost effective “non-flashy” way to cover the ugly OEM reservoir caps with a clean, tasteful design that “covers the mess” and allows the rest of your build to stand out and shine.

These decorative reservoir caps are designed for the enthusiast who understands that a well-sorted engine bay should look as refined as it performs. Manufactured using ultra-durable PA12 nylon on an industrial-grade SLS (Selective Laser Sintering) printer, these caps deliver OEM-plus aesthetics with modern manufacturing precision.

Each cap was designed in 3D and carefully printed on a $500,000 industrial HP SLS system, allowing for extremely tight tolerances, uniform wall thickness, and exceptional surface consistency. The result is a part that feels intentional—not 3D printed in the hobbyist sense, but engineered and finished to a professional standard.

Material & Durability – Why PA12 Nylon Matters

For those who don’t know, PA12 (Polyamide 12) nylon is a material widely used in OEM automotive components, aerospace ducting, and motorsports applications due to its excellent balance of strength, flexibility, and thermal stability.

Compared to lower-grade plastics or hobby-level 3D printing materials, PA12 offers:

High heat resistance, making it well-suited for under-hood environments

Excellent chemical resistance to oils, coolants, and common automotive fluids

Dimensional stability, ensuring consistent fitment over time

Impact and fatigue resistance, so the caps won’t become brittle or crack with age

Because these parts are produced using industrial SLS printing, they are fully dense and isotropic—meaning strength is consistent in all directions, unlike layered filament prints that can delaminate or warp over time.

The surface is printed with a satin-wrinkle texture, carefully chosen to mimic the look of our GMS High Flow Hood Brackets that utilize a satin black wrinkle powder coating. After printing, each cap is dyed black, creating a deep, uniform finish that resists fading and blends seamlessly into both factory and modified engine bays. The satin-wrinkle texture isn’t just cosmetic—it also helps mask fingerprints, dust, and minor wear, keeping the engine bay looking clean and intentional.

Installation is not only simple, but fully reversible. These caps install directly over your existing factory reservoir caps using a precise friction fit (no adhesives, no hardware, and no permanent modifications) They stay secure in normal driving conditions while allowing easy removal if needed. (note: due to the some slight variation in reservoir cap dimensions, a dab of RTV or silicone may be needed to secure the fitment)

Let’s be clear: these caps are purely cosmetic. They don’t change performance, pressure, or function—and that’s exactly the point. They exist for drivers who open the hood and care about what they see. For those who believe a car that runs hard should also look the part.

Because performance is expected—details are chosen.

Who These Are For…

Enthusiasts who value engine bay aesthetics

Owners building a clean, OEM-plus or show-quality look

Drivers who believe the details matter just as much as the dyno sheet

If you care about what your car looks like when the hood is open—or when the photos get posted—this is the finishing touch.

What’s in the box:

(1) Engine Coolant Reservoir Cap

(1) Windshield Washer Filler Cap

(1) Brake Fluid Reservoir Cap

(option heat exchanger cap if selected in the pull downs)